plaquette d'information sur la série de viscosimètres cinématiques svm

plaquette d'information sur la série de viscosimètres cinématiques svm de Anton Paar

Contenu du document

kinematic viscometer series

SVM series

Welcome to New Viscometry!

Progress and innovation, high-precision craft, and a passion for research – these values define Anton Paar. They underpin the viscosity measurement solutions we’ve been supplying to our customers for over 20 years. Components produced with the highest attention to detail, innovative measuring principles, and well-designed user interfaces represent our standard of quality. Building on our strong technological leadership, the SVM series is once again revolutionizing the world of viscometry, utilizing the latest technology to deliver the best kinematic viscometers on the market.

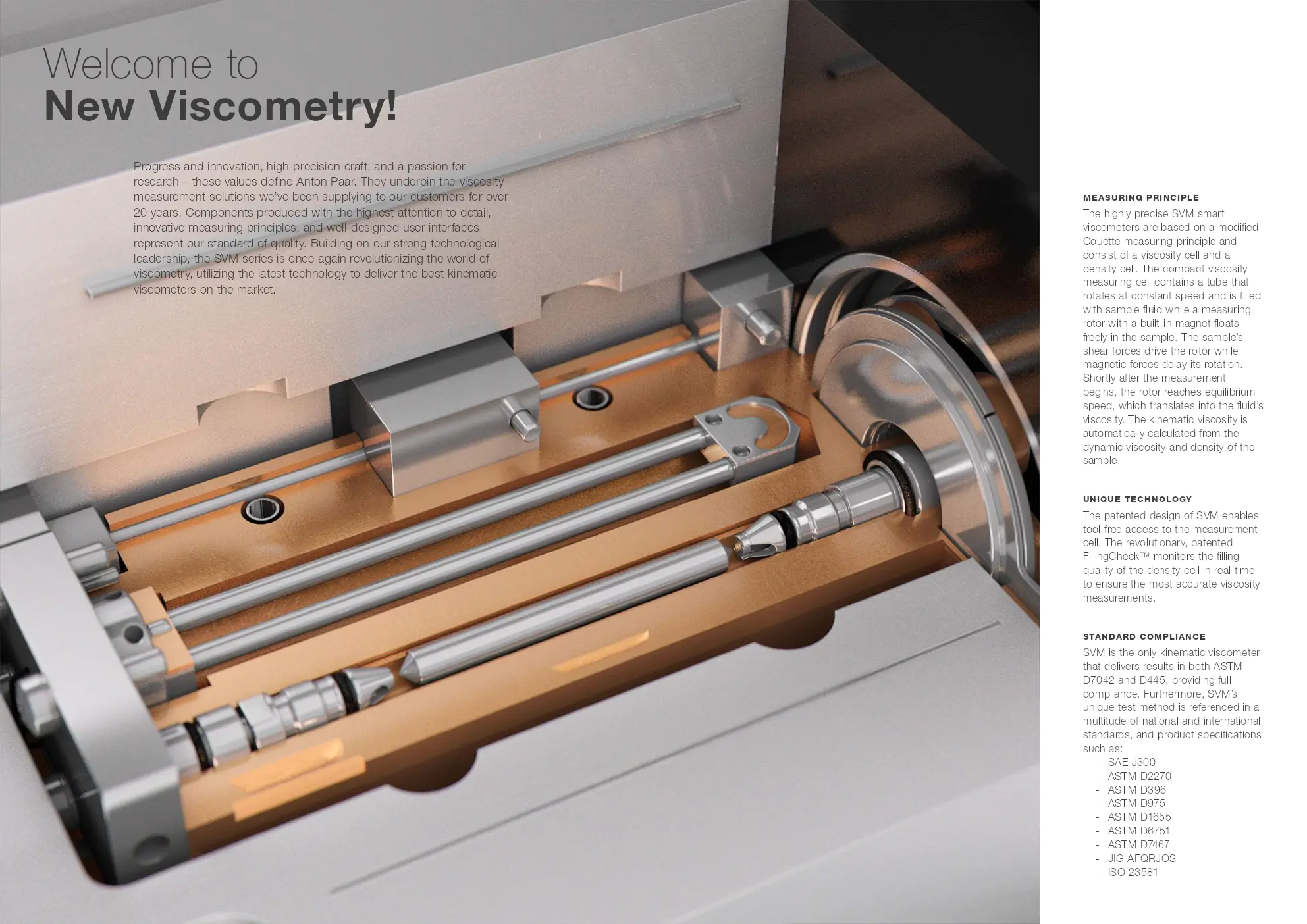

Measuring Principle

The highly precise SVM smart viscometers are based on a modified Couette measuring principle and consist of a viscosity cell and a density cell. The compact viscosity measuring cell contains a tube that rotates at constant speed and is filled with sample fluid while a measuring rotor with a built-in magnet floats freely in the sample. The sample’s shear forces drive the rotor while magnetic forces delay its rotation. Shortly after the measurement begins, the rotor reaches equilibrium speed, which translates into the fluid’s viscosity. The kinematic viscosity is automatically calculated from the dynamic viscosity and density of the sample.

Unique Technology

The patented design of SVM enables tool-free access to the measurement cell. The revolutionary, patented FillingCheck™ monitors the filling quality of the density cell in real-time to ensure the most accurate viscosity measurements.

Standard Compliance

SVM is the only kinematic viscometer that delivers results in both ASTM D7042 and D445, providing full compliance. Furthermore, SVM’s unique test method is referenced in a multitude of national and international standards, and product specifications such as:

- SAE J300

- ASTM D2270

- ASTM D396

- ASTM D975

- ASTM D1655

- ASTM D6751

- ASTM D7467

- JIG AFQRJOS

- ISO 23581

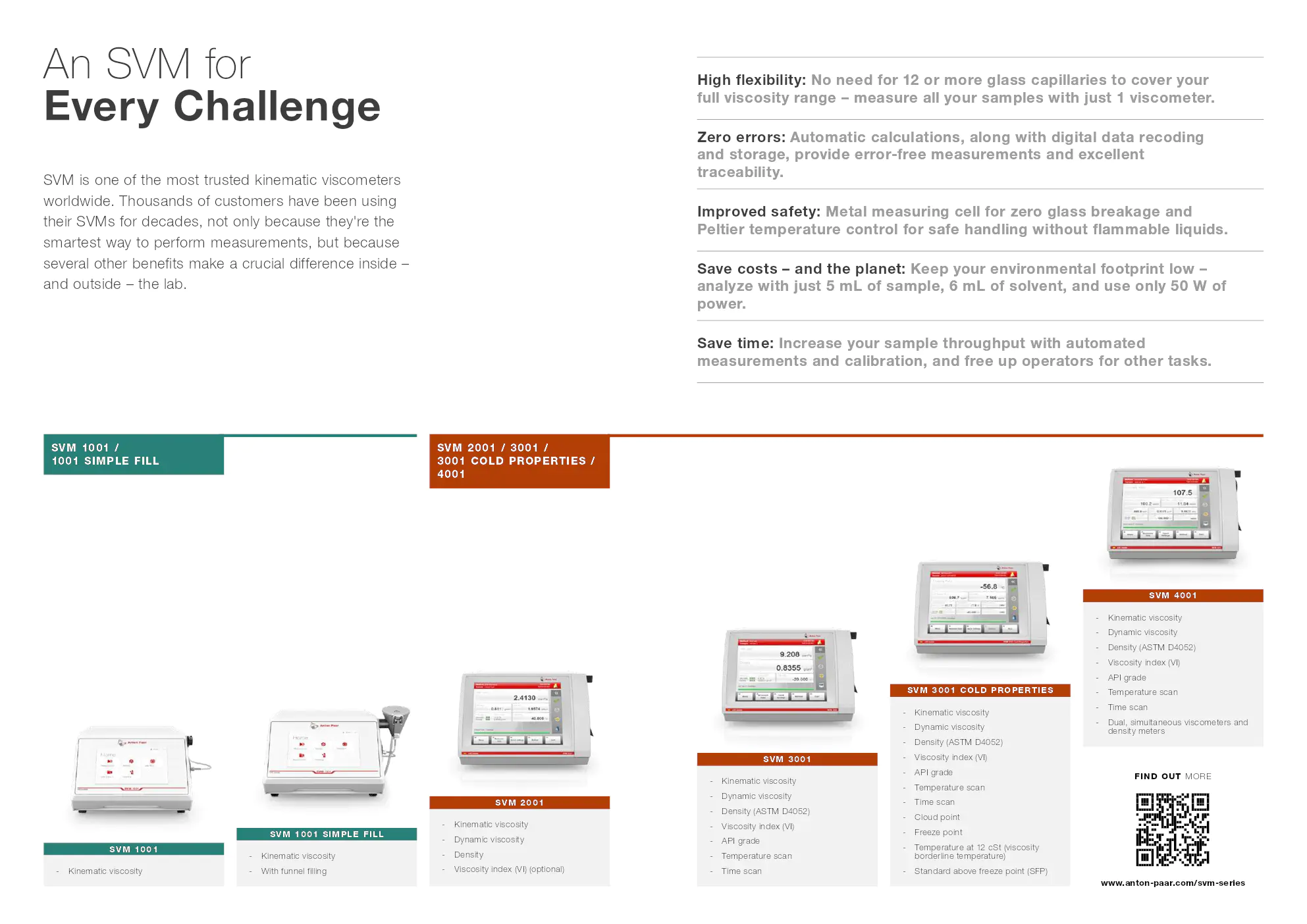

An SVM for Every Challenge

High flexibility: No need for 12 or more glass capillaries to cover your full viscosity range – measure all your samples with just 1 viscometer. Zero errors: Automatic calculations, along with digital data recording and storage, provide error-free measurements and excellent traceability. Improved safety: Metal measuring cell for zero glass breakage and Peltier temperature control for safe handling without flammable liquids. Save costs – and the planet: Keep your environmental footprint low – analyze with just 5 mL of sample, 6 mL of solvent, and use only 50 W of power. Save time: Increase your sample throughput with automated measurements and calibration, and free up operators for other tasks.

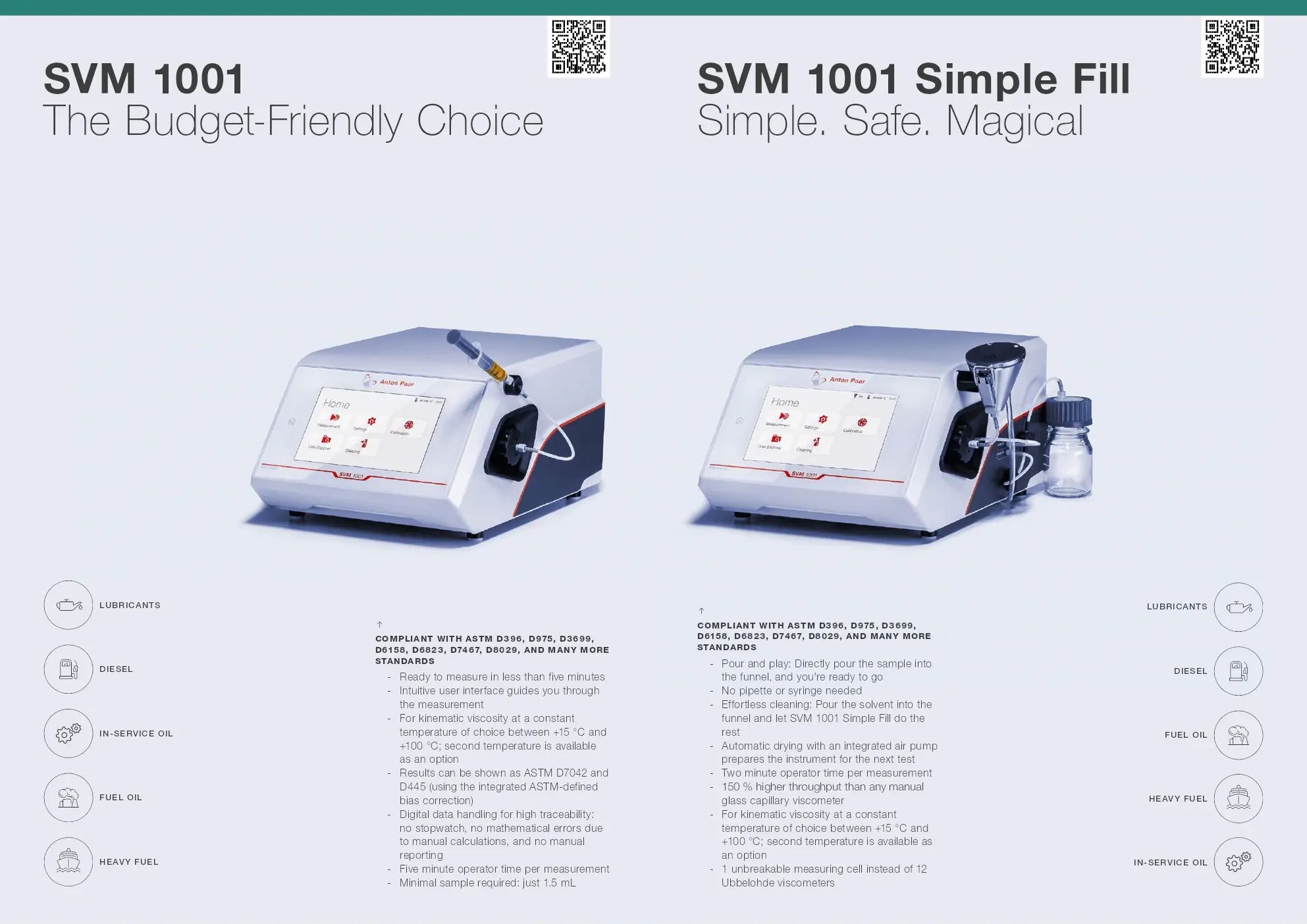

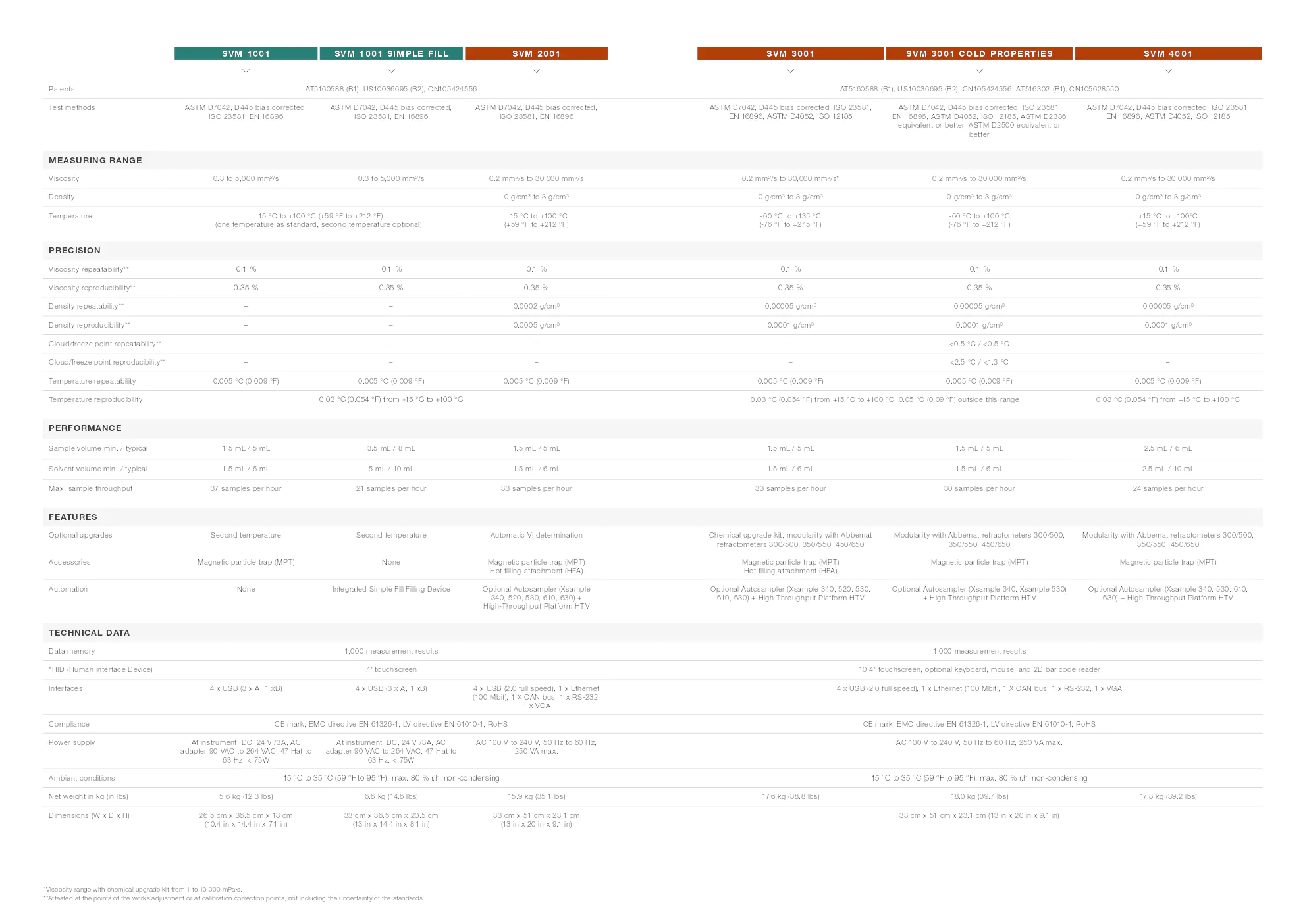

SVM 1001 / 1001 Simple Fill

The World Is Not Made of Glass: SVM 1001 and SVM 1001 Simple Fill are your budget-friendly entry tickets into the world of digital automatic kinematic viscometry. The unbreakable measuring cell lets you measure samples from diesel to lubricants without needing a stopwatch, temperature bath, or additional glass capillaries. ASTM-compliant results are delivered in both D7042 and D445. The SVM 1001 series offers 150 % higher throughput and consumes 95 % less energy and 75 % less solvent compared to manual glass capillary viscometers. With SVM 1001 Simple Fill, you can directly pour the sample into the funnel, eliminating consumable costs for pipettes or syringes and making viscosity measurements easier than ever before.

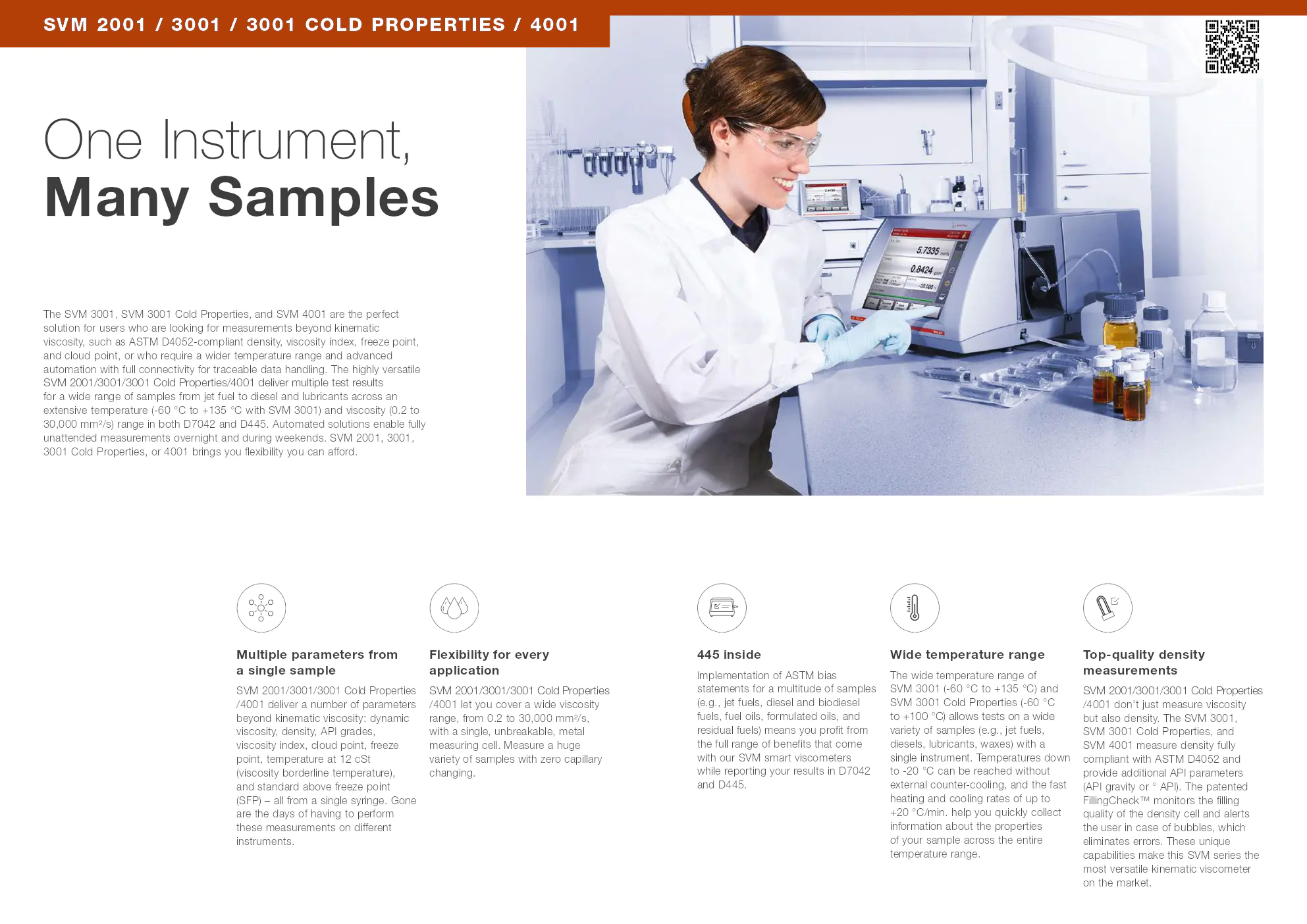

SVM 2001 / 3001 / 3001 Cold Properties / 4001

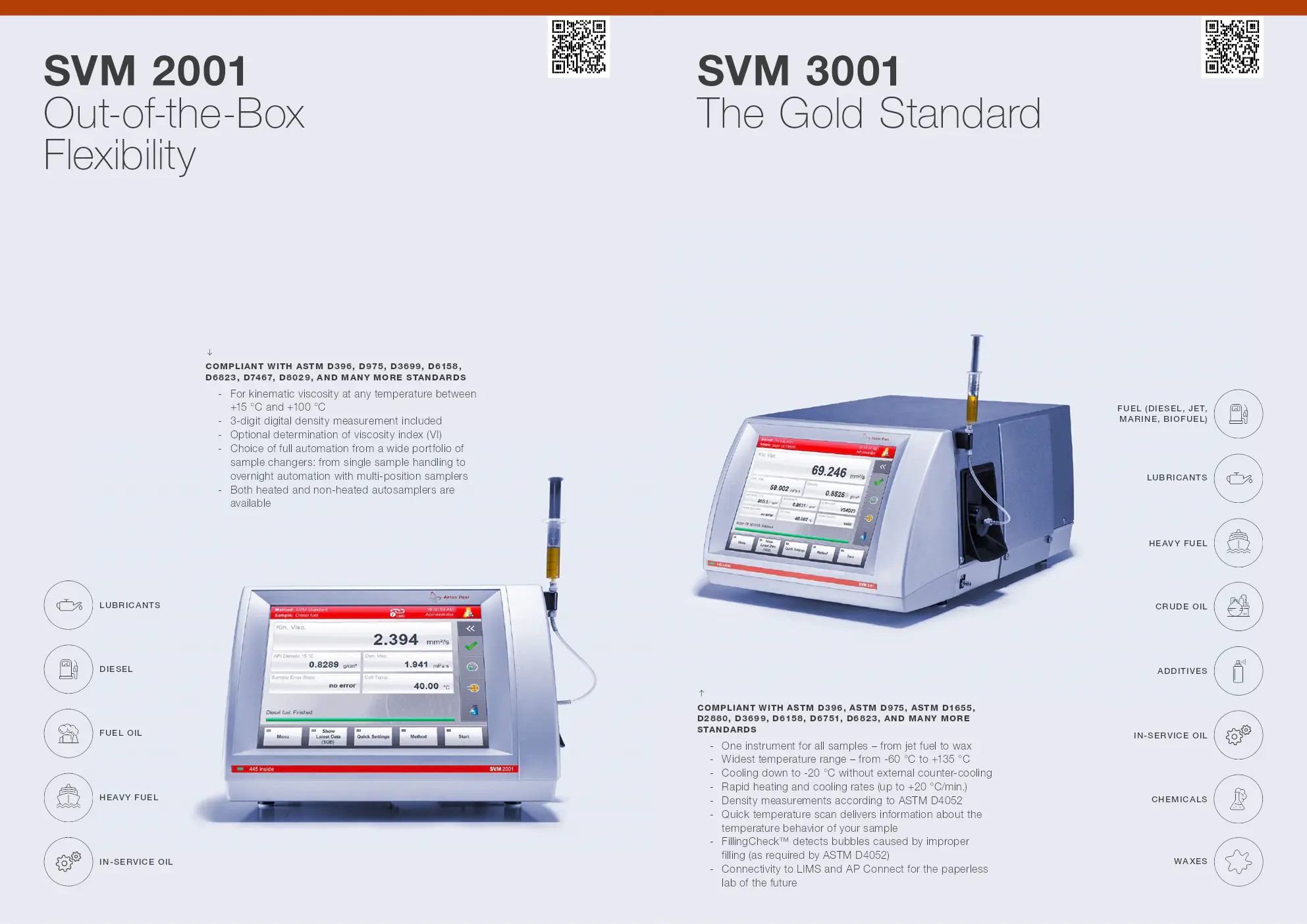

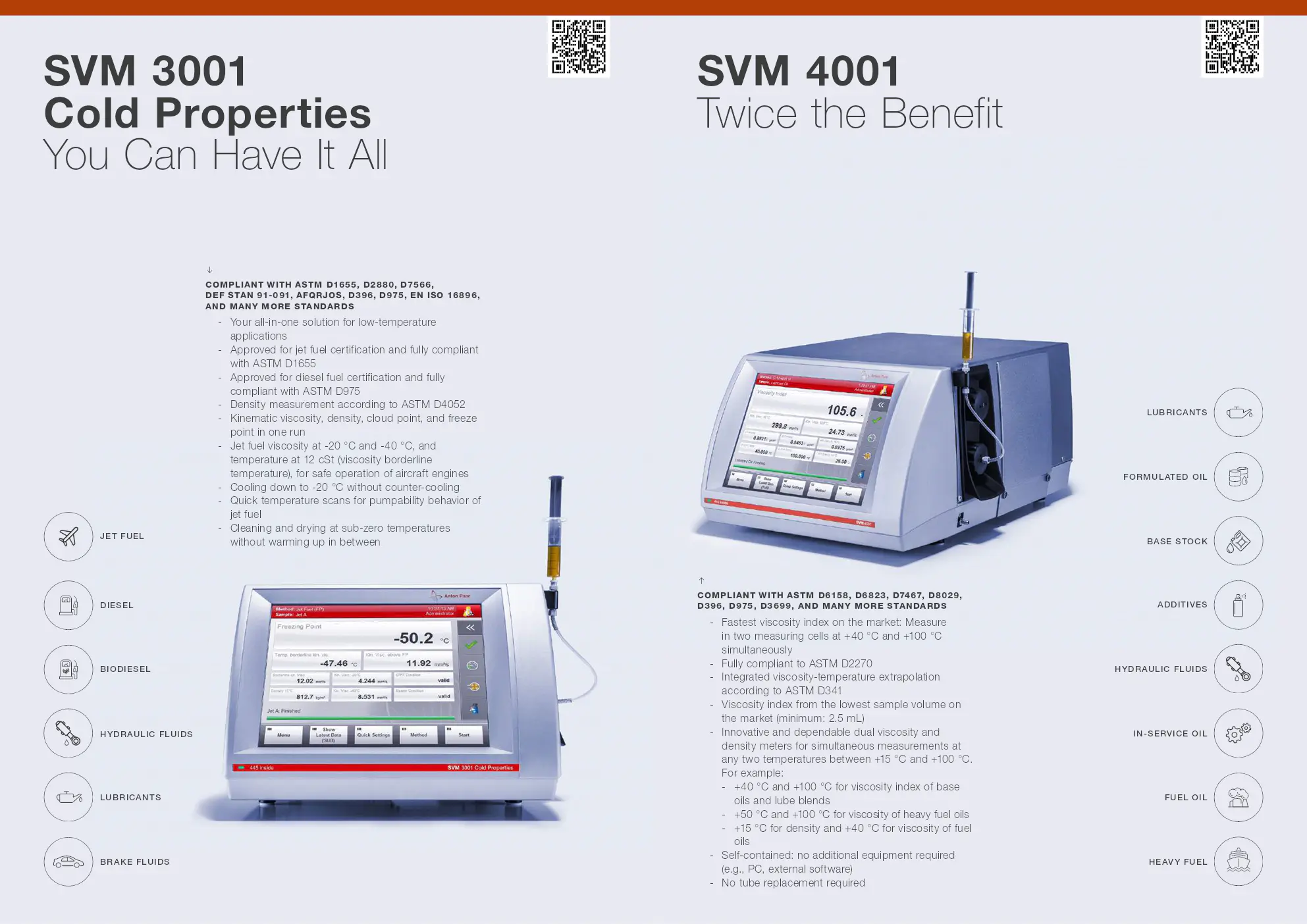

One Instrument, Many Samples: The SVM 3001, SVM 3001 Cold Properties, and SVM 4001 are the perfect solution for users who are looking for measurements beyond kinematic viscosity, such as ASTM D4052-compliant density, viscosity index, freeze point, and cloud point, or who require a wider temperature range and advanced automation with full connectivity for traceable data handling. The highly versatile SVM 2001/3001/3001 Cold Properties/4001 deliver multiple test results for a wide range of samples from jet fuel to diesel and lubricants across an extensive temperature (-60 °C to +135 °C with SVM 3001) and viscosity (0.2 to 30,000 mm²/s) range in both D7042 and D445. Automated solutions enable fully unattended measurements overnight and during weekends. SVM 2001, 3001, 3001 Cold Properties, or 4001 brings you flexibility you can afford.

Customization That Delivers Results

MAKE THE MOST OF YOUR SAMPLE: Modulyzers provide multiple parameters from a single sample in only one measuring cycle, delivering all the results you need on one screen at the push of a button. THE ULTIMATE LUBE ANALYZER: Modulyzer Oil determines the viscosity index and carbon-type analysis in a single setup in one run – it’s a real time saver for laboratories dealing with the quality control of base oils and formulated lubricants such as engine, gear, or transformer oils. Analysis of carbon-type composition and carbon distribution is performed according to ASTM D2140 and D3238. All parameters are automatically calculated and displayed on the SVM screen within six minutes. Choose one turnkey solution instead of three separate measurements. THE ALL-IN-ONE JET FUEL ANALYZER: Modulyzer Jet Fuel is a versatile solution for jet fuel analysis, which delivers crucial parameters such as viscosity, density, cloud point, freeze point, temperature at 12 cSt, and refractive index – all in a single test. With this configuration, jet fuel certification according to ASTM is economical and resource-optimizing. Operational costs are minimal thanks to low sample and solvent volumes, as well as low energy consumption. In short, Modulyzer Jet Fuel is the best solution on the market at the most competitive price.

Support & Education

Every challenge can be overcome with the right partner. From helping you find the right measurement system to giving you all the background information and education you need, we at Anton Paar are committed to outstanding service and support – whenever you need it. We're confident in the high quality of our instruments. That’s why we provide a full warranty for three years.

- SIGN UP FOR DEMOS & WEBINARS: You never stop learning. Neither do we. We regularly offer free online webinars and demonstrations where you can learn about various viscometry topics and meet our experts. Recordings of our previous webinars are available in our library. Interested in an exclusive live demonstration? Then get in touch.

- DIG IN TO OUR EXTENSIVE KNOWLEDGE DATABASE: Access our big content hub of application reports, product documentation, and tutorial videos, or pick up some background knowledge from our Wiki.

- CONTACT OUR EXPERTS: We're proud of our reputation for excellent service and support. We have over 3,400 employees worldwide, a network of more than 30 Anton Paar subsidiaries, and over 60 responsible partners – so one of our viscometry experts is always just a call away and happy to help.