brochure de l'analyseur onh par élémentar

document sur l'analyseur ONH d'Elementar pour l'analyse de l'oxygène, de l'azote et de l'hydrogène

Contenu du document

ONH

Oxygen, Nitrogen and Hydrogen Analysis by High-Temperature Induction Heating

- High sensitivity

- High data quality

- Extreme durability

- Great flexibility

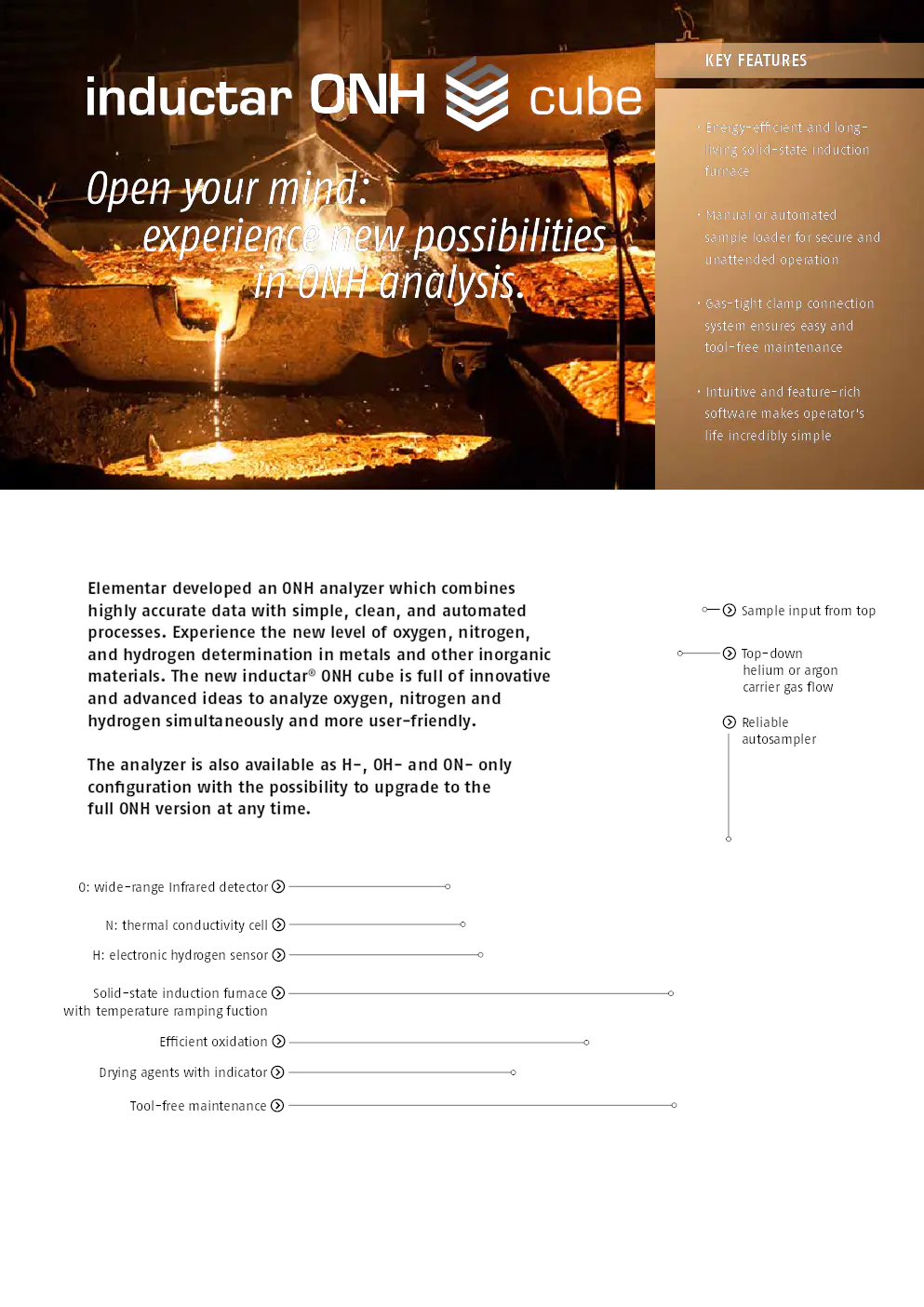

KEY FEATURES

- Energy-efficient and long-living solid-state induction furnace

- Manual or automated unattended operation

- Gas-tight clamp connection system ensures easy and tool-free maintenance

- Intuitive and feature-rich software makes operator's life incredibly simple

Elementar developed an ONH analyzer which combines highly accurate data with simple, clean, and automated processes. Experience the new level of oxygen, nitrogen, and hydrogen determination in metals and other inorganic materials. The new inductar® ONH cube is full of innovative and advanced ideas to analyze oxygen, nitrogen, and hydrogen simultaneously and more user-friendly. The analyzer is also available as H-, OH- and ON- only configuration with the possibility to upgrade to the full ONH version at any time.

- O: wide-range Infrared detector

- N: thermal conductivity cell

- H: electronic hydrogen sensor

- Solid-state induction furnace with temperature ramping function

- Efficient oxidation

- Drying agents with indicator

- Tool-free maintenance

Innovative ideas

For the first time, a powerful but energy-efficient solid-state induction furnace enables extremely high temperatures up to 3000?°C. Combined with high-performance detectors, the inductar ONH cube shows excellent accuracy and outstanding reliability.

Freely programmable methods

Fusion properties vary for different materials. Thus, it is important to adjust the temperature individually for reliable results. The solid-state induction furnace and Elementar's advanced software make it possible to tailor the temperature profile for every specific application. By this, complete fusion and accurate results are always ensured for a broad variety of inorganic materials.

Automated analysis

The fast and precise autosampler with its innovative robotic arm (patent pending) allows unattended operation. The sequence of all sample positions is user configurable and can be changed at any time. Automation is further accomplished by automatic weight transfer from balance, barcode reader support and easy LIMS integration. The inductar ONH cube is controlled via an intuitive, feature-rich, multi-language software. It is easy to use and configurable to fulfill all requirements in R & D, quality control, and high-throughput laboratories.

ADVANTAGES BY INDUCTION

Induction heating is in many respects advantageous for ONH analysis. The first advantage is obviously that no electrodes need to be frequently cleaned, which results in less maintenance and more reliable results. Second, as the graphite crucible is not connected to cooled electrodes, the sample container can be completely outgassed. Third, power and therewith the temperature can be smoothly controlled, which ensures best data quality. Moreover, the induction furnace is highly energy efficient, which reduces power consumption and makes it more flexible regarding the required lab infrastructure.

Advanced ONH analysis for inorganic materials

OXYGEN NITROGEN HYDROGEN

- STEEL 0.0052 [%] ± 0.0004

- STEEL POWDER FOR 3D PRINTING 0.0526 ± 0.0012 [%]

- TITANIUM 1 0.4853 ± 0.0043 [%]

- TITANIUM 2 0.1209 ± 0.0004 [%]

- COPPER (Cu) 0.0327 ± 0.0013 [%]

- COPPER OXIDE (CuO) 20.29 ± 0.19 [%]

- NICKEL OXIDE (NiO) 21.84 ± 0.27 [%]

- ALUMINIUM ALLOY (AlSi) 0.0700 ± 0.0012 [%]

- MgN BASIS 2.72 ± 0.02 [%]

IDEAL SOLUTION FOR

- Steel mills

- Foundries

- Aerospace industry

- Automotive industry

- Semiconductor industry

Sample Types Analyzed:

- Steel

- Cast iron

- Titanium alloy

- Copper alloy

- Other metals and inorganics

High Sensitivity: Outstanding sensitivity thanks to high performance, state-of-the-art technology.

High Data Quality: Outstanding precision and accuracy through high performance combustion. Long-term stability of calibration.

Extreme Durability: Outstanding robustness and longevity thanks to state-of-the-art technology.

Great Flexibility: Wide range of materials analyzable.

Elementar – your partner for excellent elemental analysis

Elementar is the world leader in high performance analysis of organic and inorganic elements. Continuous innovation, creative solutions and comprehensive support form the foundation of the Elementar brand, ensuring our products continue to advance science across agriculture, chemical, environmental, energy, materials and forensics markets in more than 80 countries.

Elementar Analysensysteme GmbH

Elementar-Straße 1 · 63505 Langenselbold (Germany)

Phone: +49 (0) 6184 9393-0 | info@elementar.de | www.elementar.de