brochure sur les analyseurs de surface et de taille de pores nova series

Présentation des analyseurs de surface et de taille de pores nova series.

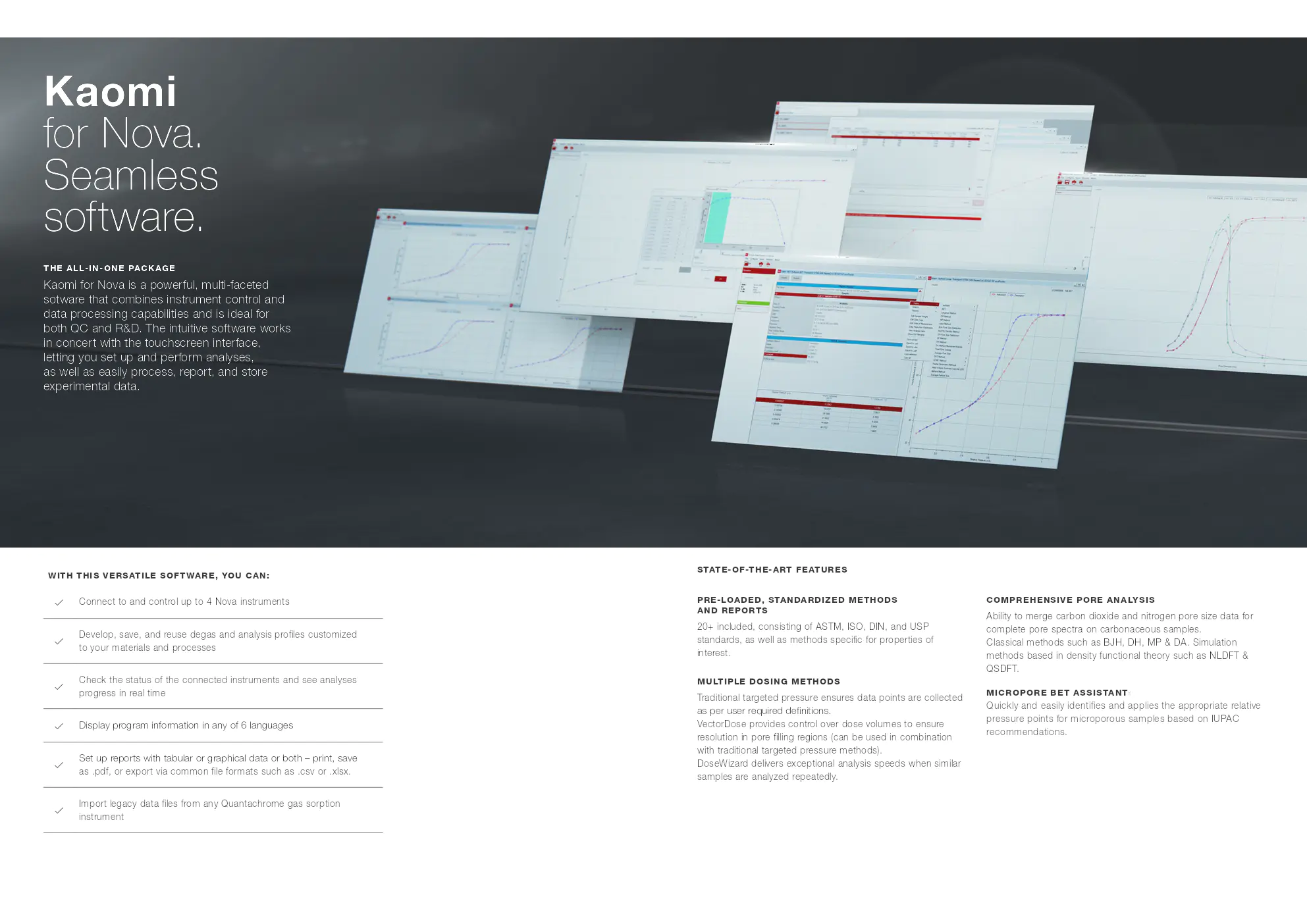

Contenu du document

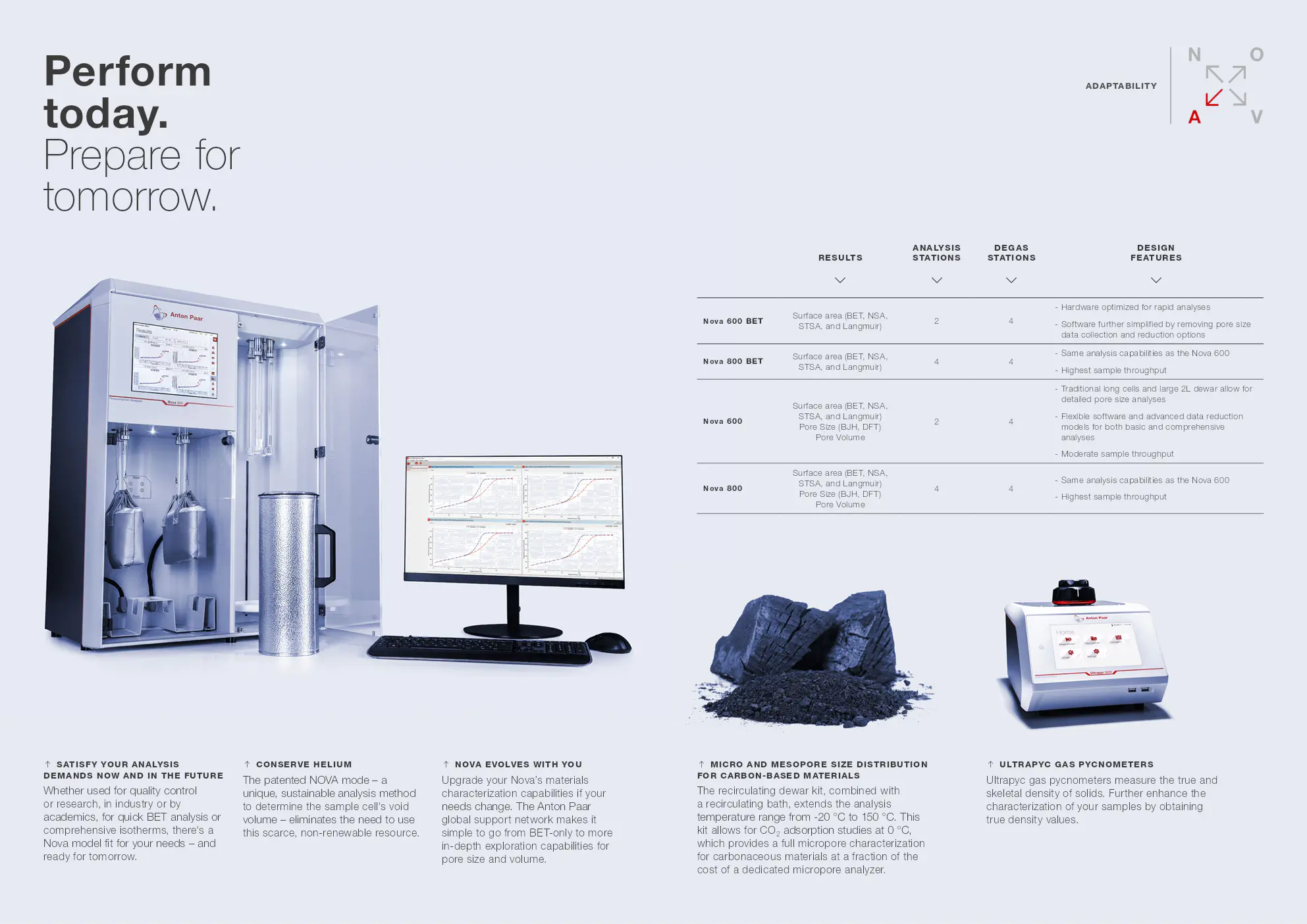

Nouveau produit : Nova Series

Analyseurs de surface et de taille de pores

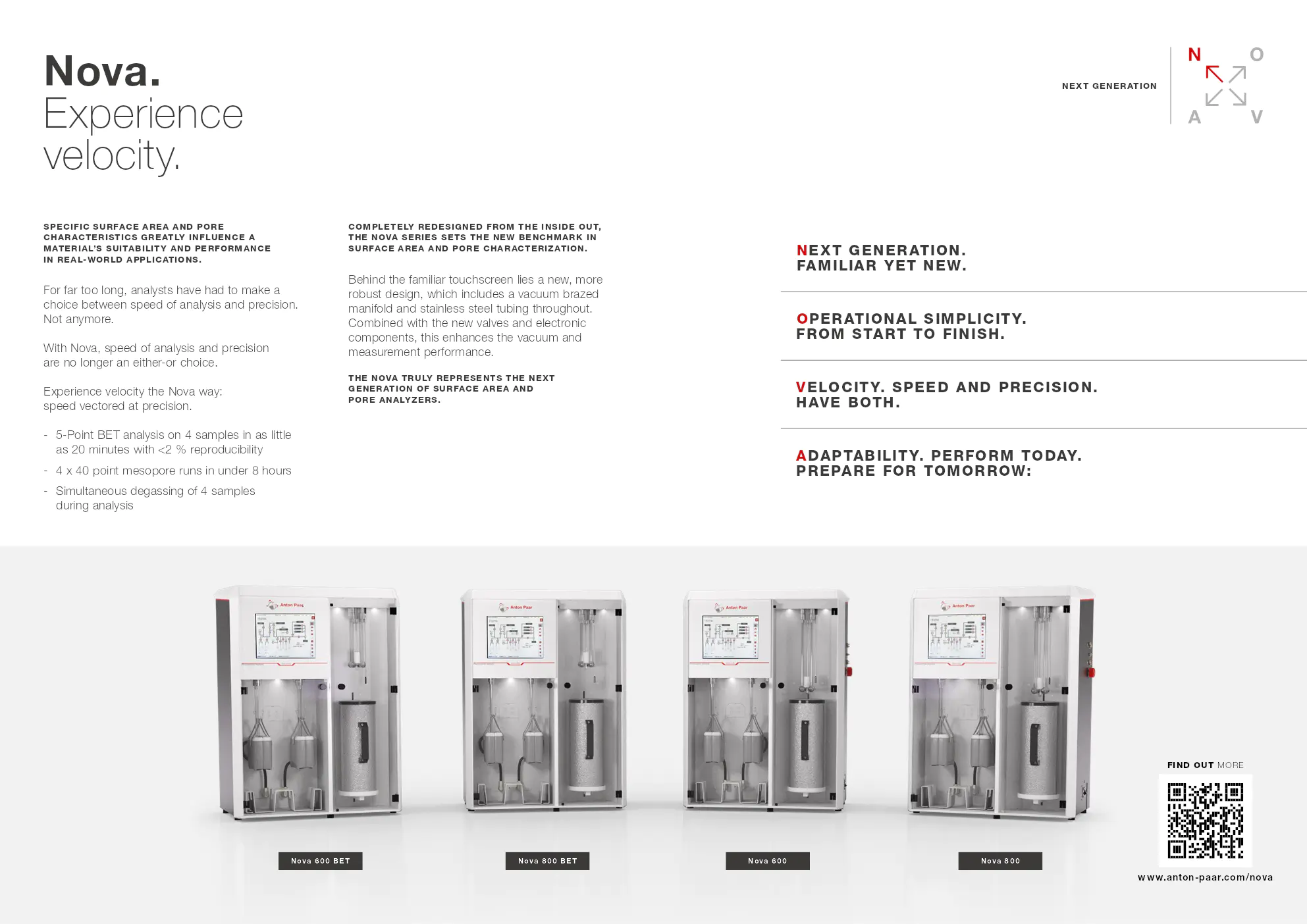

Nova. Découvrez la vitesse nouvelle génération.

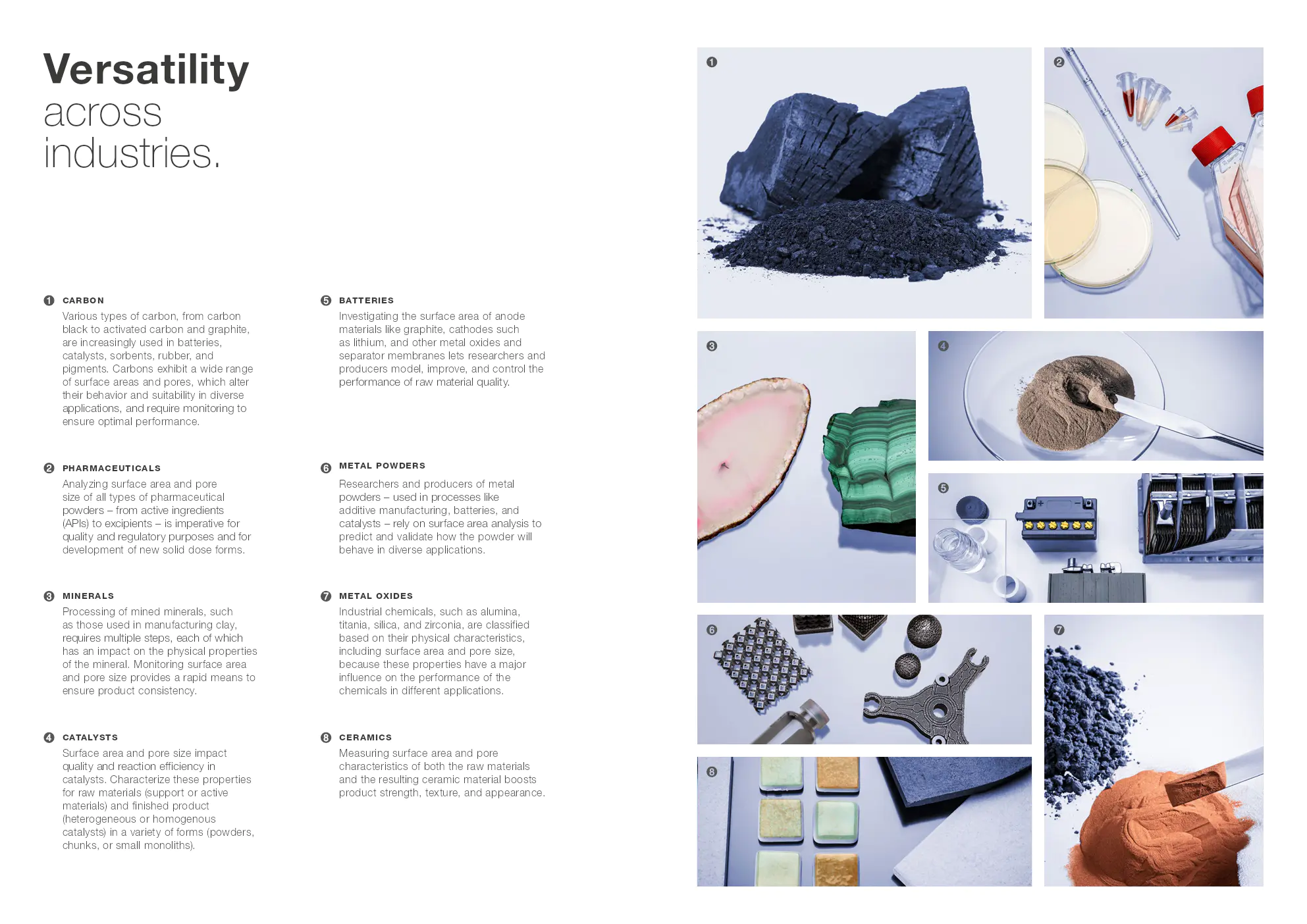

- Les caractéristiques spécifiques de surface et de taille de pores influencent grandement l'aptitude et la performance d'un matériau dans des applications réelles.

Pour bien trop longtemps, les analystes ont dû choisir entre rapidité d'analyse et précision. Ce n'est plus le cas.

Avec Nova, la rapidité d'analyse et la précision ne s'excluent plus mutuellement. Découvrez la vitesse à la manière de Nova : rapidité orientée vers la précision.

- Analyse BET 5 points sur 4 échantillons en aussi peu que 20 minutes.

NEXT GENERATION

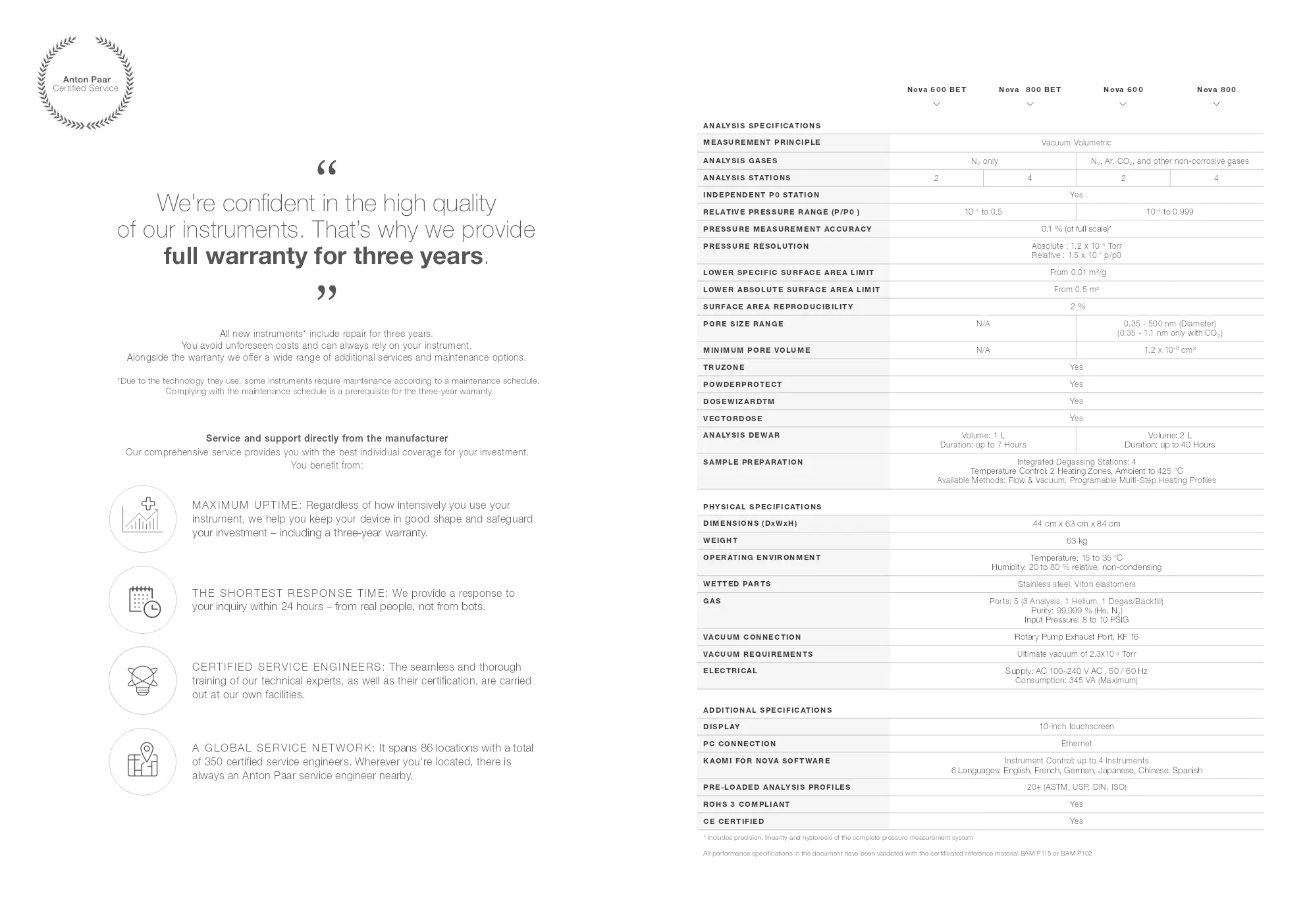

Complètement redéfinie de l'intérieur, la série Nova établit une nouvelle référence en caractérisation de surface et de pores. Elle est à la fois familière et nouvelle.

Derrière l'écran tactile familier se cache une conception robuste comprenant un collecteur soudé sous vide et des tubes en acier inoxydable dans tout l'appareil. Combinée avec les nouvelles valves et composants électroniques, ceci améliore les performances de vide et de mesure.

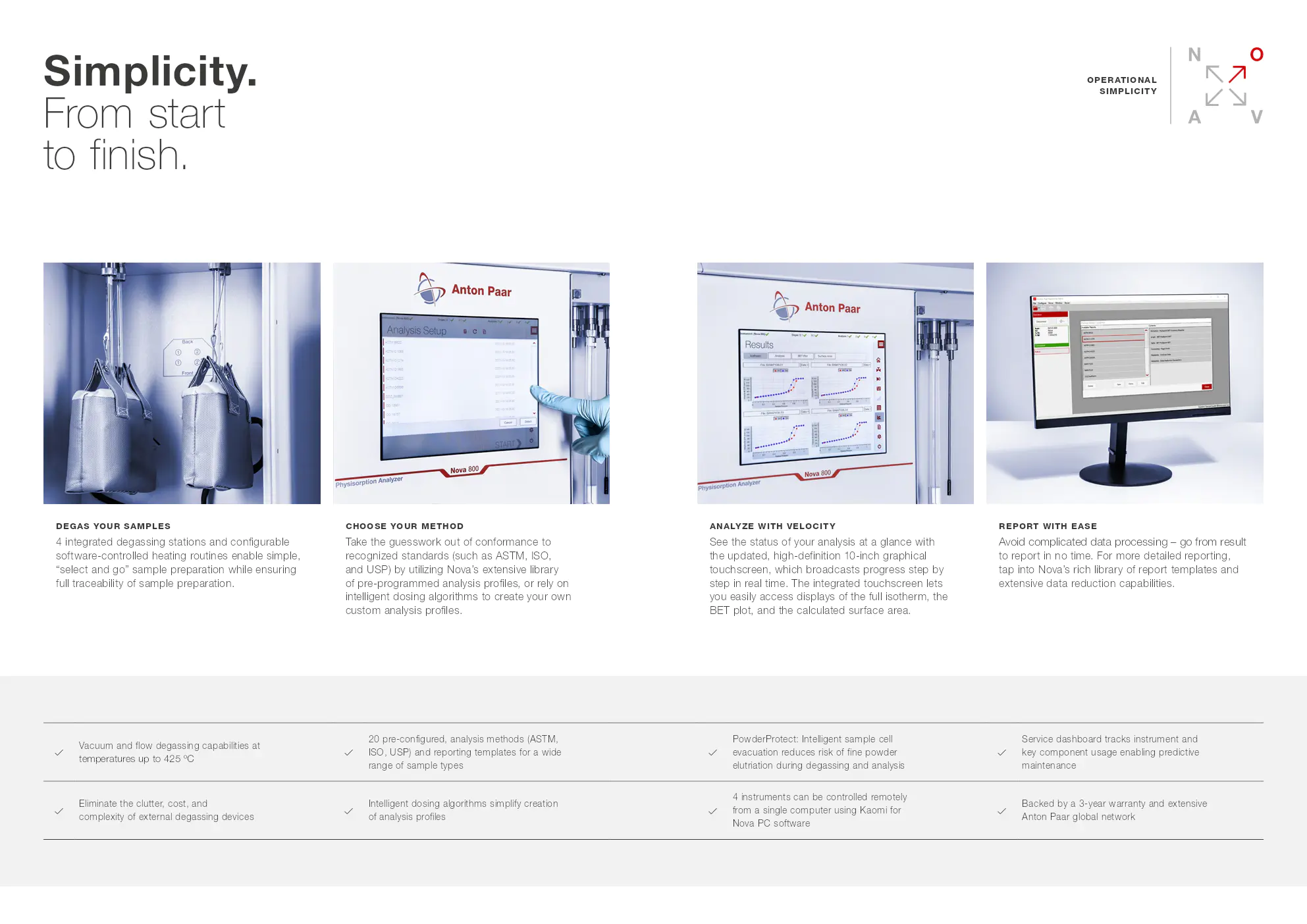

SIMPLICITÉ OPÉRATIONNELLE DE DÉBUT À FIN

La Nova représente véritablement la prochaine génération d'analyseurs de surface et de pores, alliant vitesse et précision, sans compromis.