Document

I17IP001EN-A_Autotap_Brochure_

Contenu du document

AUTOTA P

automated tap density analyzers

Quantachrome

Quantachrome

ASTM B527

ASTM D4164

ASTM D4781 IDF 134

ISO 787-11 ISO 3953

ISO 8460

ISO 8967

ISO 9161

JIS K5101-12-2 JIS Z 2512MPIF 46

USP<616>method II

(preharmonization)

USP<616>method I

(harmonized)

JP 3.01 Part 2 Method 1

(harmonized)

PH. EUR. 6.8 Method 1

(harmonized) (metallic powders)

(formed catalysts)

(fine catalysts)

(dried milk)

(pigments)

(metallic powders)

(instant coffee)

(dried milk)

(uranium dioxide powder)

(pigments)

(metallic powders)

(metal powders)

(pharmaceutical powders)

(pharmaceutical powders)

(pharmaceutical powders)

(pharmaceutical powders)

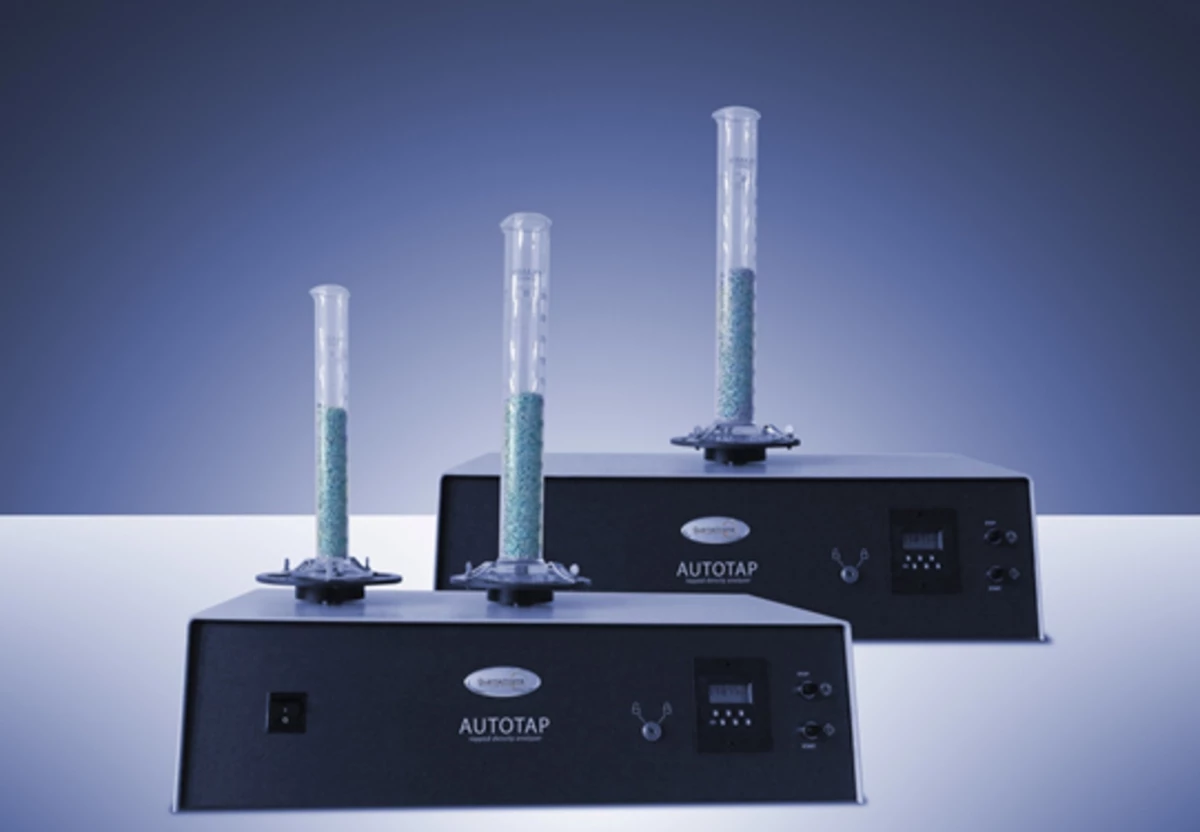

To measure tap density, samples are placed in standard graduated

cylinders and mounted on a universal tap platform designed to

accommodate cylinders from 10mL to 500mL. After noting the

initial volume and weight of the material, the number of desired

taps is entered and tapping started. When the specified number

of taps is completed, tapping stops automatically. Reading of the

powder surface is facilitated by automatic rotation of cylinders

during tapping which promotes a flat powder interface.

If the material characteristics are unknown, tapping may be

done step-wise by user specified numbers of taps, while noting

or graphing the results until the volume becomes constant.

Once the tapping behavior is known, the proper number of

taps, typically thousands, including a significant excess (to

account for future variability between samples) can be preset on

subsequent runs, thus freeing the operator for other work.

A noise reduction cabinet is available which can reduce the

tapping noise levels by 15 dBA* or more.

*

Actual improvement depends on local factors such as bench, ceiling height etc

The apparent bulk densities of powdered, granular of flaked

materials are highly dependent on the manner in which the

particles are packed together due to cohesion and shape

effects. Furthermore, handling or vibration of particulate

material causes the smaller particles to work their way into

the spaces between the larger particles. The geometric space

occupied by the powder decreases and its density increases.

Ultimately, no further natural particle packing takes place with-

out the addition of pressure and maximum particle packing

is achieved. Under controlled conditions of tapping rate, tap

force drop and cylinder diameter, this condition of maximum

packing efficiency is highly reproducible. Tap density measure-

ment is formalized in a number of international standards

to which both Autotap models conform.

Visit www.quantachrome.com for more detailed

instruments specifications and downloadable brochures.

ACCESSORIES

cabinet

Noise Reduction Cabinet

A sound-insulated enclosure is available that

accommodates either Autotap model. The

noise from tapping can be reduced by up to

15 dBA (actual improvement depends on local

factors such as bench material and ceiling

height). The doors can be locked for added

safety and security.

Dimensions:

76.2cm (30”) W x 38.1cm (15”) D x 76.2cm (30”) H.

Weight: 28kg .

TAPPED

density

1

Key Lock

The units’ control panel can be disabled

thanks to a lock at the front of the instrument

which enables the user to prevent others

from tampering with the counter settings.

Standards Suitability

Quantachrome

Electrical

Voltage:

Frequency:

Power (max): Connection: 110-120 V or 220-240V

50/60 Hz

150 VA

Grounded, single-phase outlet

AUTOTAP INSTRUMENT

features

Environmental

Temperature:

Max. Relative Humidity: 15ºC - 40ºC

80%

Ordering Information

Autotap, 50 Hz, 100-115v:

Autotap, 50 Hz, 220-240v:

Autotap, 60 Hz, 100-115v:

Autotap, 60 Hz, 220-240v:

Dual Autotap, 50 Hz, 100-115v:

Dual Autotap, 50 Hz, 220-240v:

Dual Autotap, 60 Hz, 100-115v:

Dual Autotap, 60 Hz, 220-240v: Noise Reduction Cabinet: p/n 02106-50-100-1

AP Nr. 196351

p/n 02106-50-1

AP Nr. 192954

p/n 02106-60-1

AP Nr. 192955

p/n 02106-60-220-1

AP Nr. 196352

p/n 02105-50-100-1

AP Nr. 196349

p/n 02105-50-1

AP Nr. 192979

p/n 02105-60-1

AP Nr. 192980

p/n 02105-60-220-1

AP Nr. 196350

p/n 62105-NRC

AP Nr. 194978

www.quantachrome.com

Performances

Stations:

Cylinder Sizes:

Nominal Tapping Rate:

Tapping (drop) Height: Tap Counter:Display:

Platform Rotation:

Sample Weight Limits:

Controls:

Lock-out: Autotap: 1 Dual Autotap: 2

250 mL standard; 10 mL, 25 mL, 50 mL,

100 mL, 500 mL, 1000 mL optional

1000 mL requires auxillary plate

quick-change assembly (p/n 01470-5830 /

AP Nr. 193228)

260 min-1

3mm (0.125 inch)

1-999999

LCD, automatic countdown, automatic reset

Automatic

900g (2 lb) with no effect on tapping rate

1800g (4 lb) with 5% reduction in tapping rate

2275g (5 lb) with 15% reduction in tapping rate

on/off, start, stop, counter reset

keyed lock for tap counter

Power Switch Digital Counter

Start Button

Lock

Stop Button

Graduated Cylinder Holder

Physical

Height:

Width:

Depth:

Weight: 175 mm (7 in) excluding cylinders

540 mm (21 in)

280 mm (11 in)

11 kg (24 lbs) Autotap

14 kg (31 lbs) Dual Autotap

SPECIFICATIONS

2

Quantachrome

The quality of Quantachrome’s after sales service support is the reason we

are proud to maintain life time relationships with our customers.

Renowned innovator for today’s porous materials community.

Our policy of continuous development may cause the information and specifications contained herein to change without notice or liability.

Field Service

Our global service staff assure you that Quantachrome Instruments will continue

to be the reliable engines of material characterization laboratories. We offer you

the flexibility of choosing from service contracts tailored to provide you with the

response time, service package, and spare parts discounts that best fit your needs.

Spare Parts

Quantachrome spare parts are certified to work with our instruments. We provide

rapid response spare parts orders, and keep large inventories of replacement parts

and hardware available.

Application Lab

Our fully equipped, state-of-the-art powder characterization laboratory

(email: application.qt@anton-paar.com), provides the option of contracting for

expert testing services. Laboratory services are also available to validate the

applicability of our products prior to your purchase using your actual samples.

Lifetime Application Support

We view the field support of our instruments as an essential component of our

business strategy. Our expert scientists are always available to answer questions

on applications, or the use of our instruments. We do this as a standard service

regardless of whether you have a service contract with us or not.

Partners in Science

Quantachrome has a scientific research department consisting of world renowned

experts in material characterization. Our staff, led by team conducts collaborative

research projects with leading material research labs around the world. They

regularly publish articles in leading peer reviewed journals, and speak at technical

symposiums around the world.

For almost half a century Quantachrome’s

scientists and engineers have revolution-

ized measurement techniques and

designed instrumentation to enable the

accurate, precise, and reliable character -

ization of powdered and porous

materials. We have an unwavering

commitment to providing state of the art

technology, along with superior and

unparalleled customer service and

support.

Our commitment to customers is to

support you before, during, and after

the sale throughout the lifetime of our

instruments. This is a big commitment

because our products are so robust and

reliable that we regularly find many still

in use for decades.

Corporate Headquarters-USA

Quantachrome Instruments

a brand of Anton-Paar

1900 Corporate Drive

Boynton Beach, FL 33426

www.quantachrome.com

Trademarks and registered trade mark are the

property of their respective owners. Serving Porous

Materials and Powder

Characterization Needs

Since 1968

© 2018 Quantachrome Corporation I17IP001EN-A

Entreprise(s) concernée(s) :

Produit(s) concerné(s) :

Date d'upload du document :

mardi 5 janvier 2021