Document

brochure du produit hit 300 de nanoindentation tester

Brochure sur le nanoindentation tester hit 300

Contenu du document

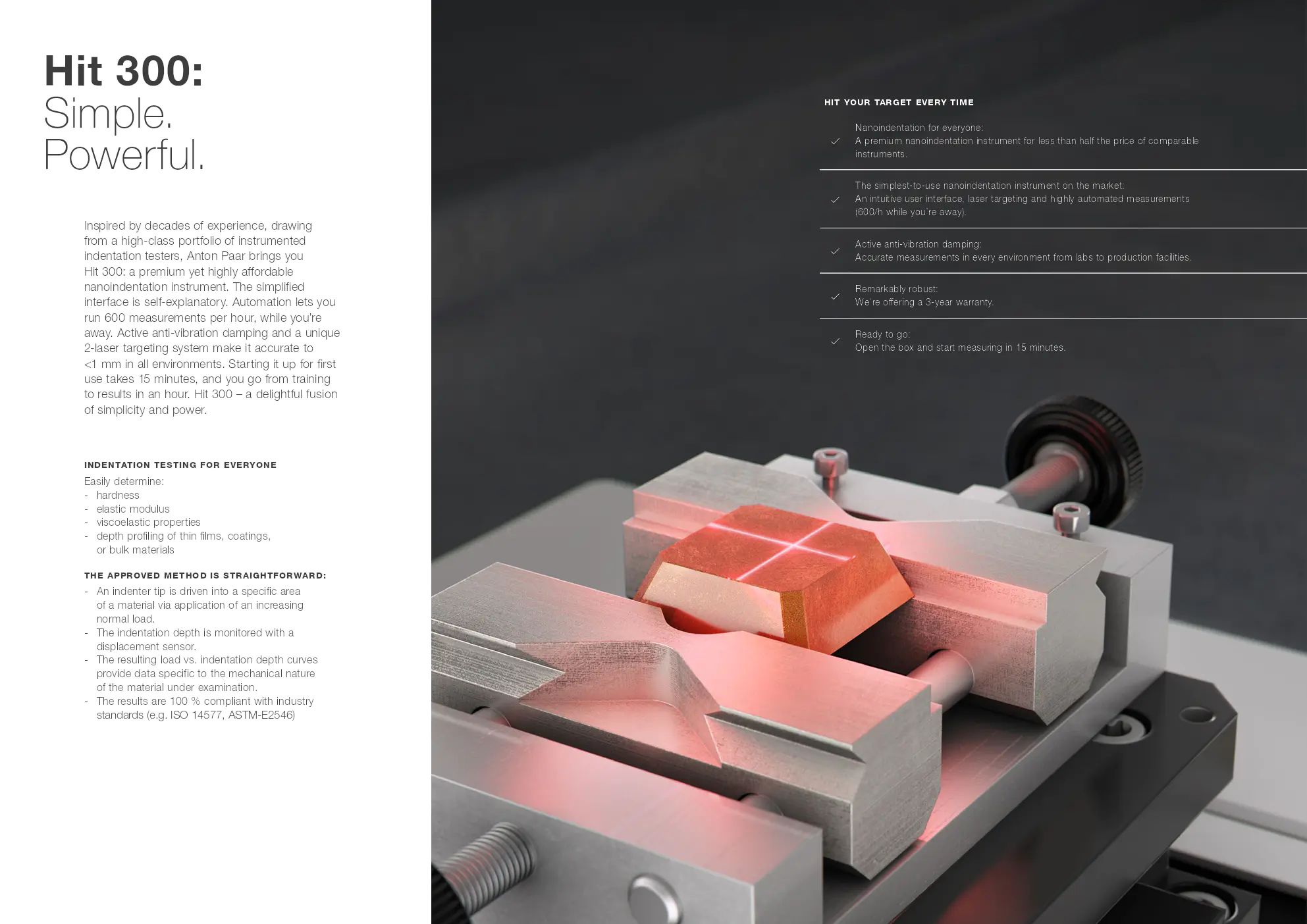

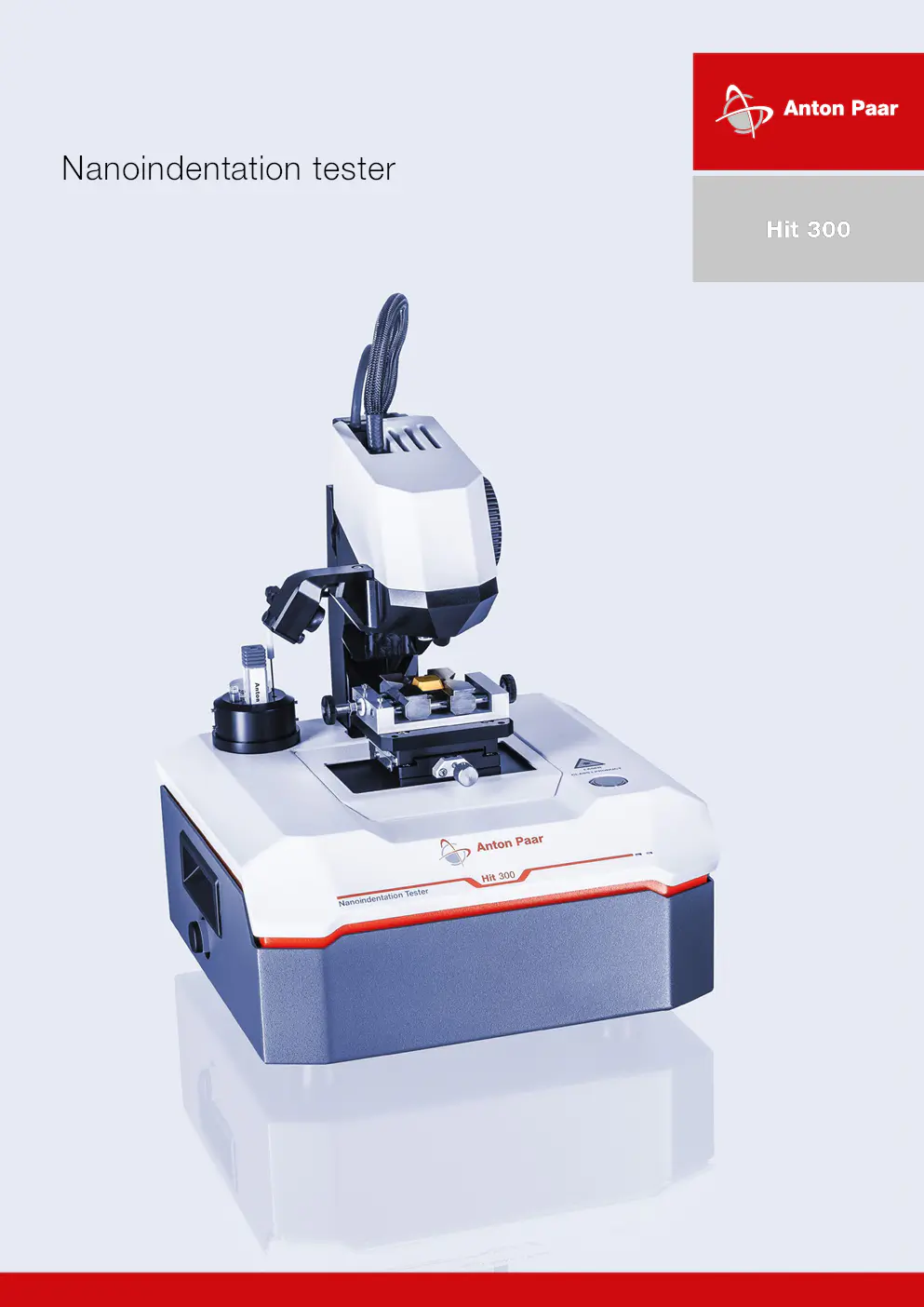

Hit 300: simple et puissant

HIT YOUR TARGET EVERY TIME

Nanoindentation pour tous:

- Un instrument de nanoindentation haut de gamme pour moins de la moitié du prix des instruments comparables.

- L'instrument de nanoindentation le plus simple à utiliser sur le marché:

- Interface utilisateur intuitive, ciblage laser et mesures hautement automatisées (600/h pendant votre absence).

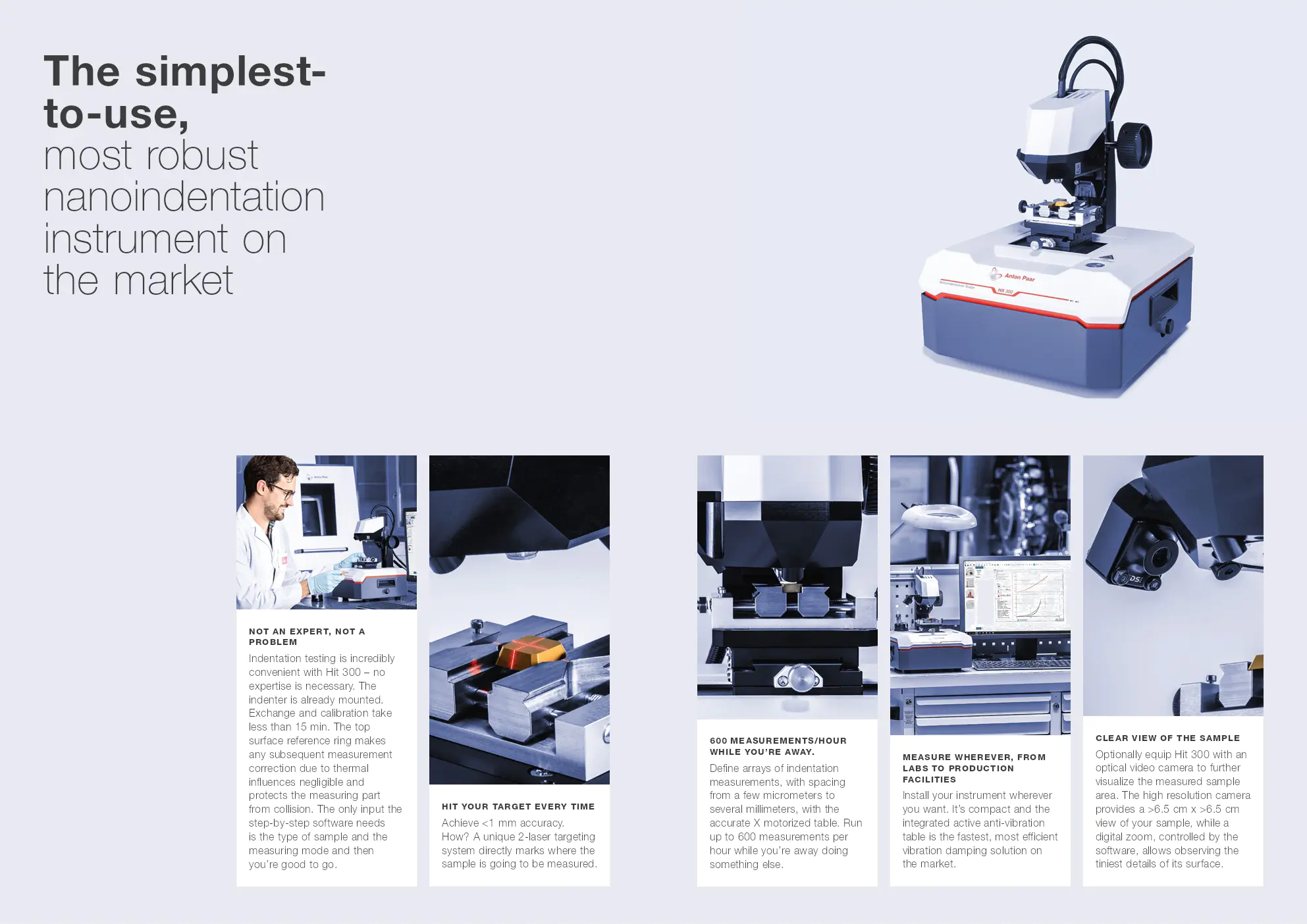

Inspiré par des décennies d'expérience, tirant parti d'un portefeuille haut de gamme de testeurs d'indentation instrumentés, Anton Paar vous présente le Hit 300 : un instrument de nanoindentation haut de gamme mais très abordable. L'interface simplifiée est explicite. L'automatisation vous permet d'effectuer 600 mesures par heure en votre absence. Le système de régulation active des vibrations et un système de ciblage à 2 lasers unique le rendent précis à 6,5 cm x >6,5 cm.

- Amortissement anti-vibration actif : Des mesures précises dans n'importe quel environnement, des laboratoires aux installations de production.

- Remarquablement robuste : Nous offrons une garantie de 3 ans.

- Prêt à l'emploi : Ouvrez la boîte et commencez à mesurer en 15 minutes.

Entreprise(s) concernée(s) :

Produit(s) concerné(s) :

Date d'upload du document :

vendredi 5 novembre 2021