brochure sur la densité solide des produits pharmaceutiques

évaluation des propriétés d'écoulement et de porosité des comprimés

Contenu du document

Solid Density of Pharmaceuticals: Assessing Flow Properties of Powders and Open Porosity of Tablets

Relevant for: pharmaceuticals, excipients, flowability, porosity, pycnometry, tapped density

Flow properties of pharmaceutical powders, as well as the open porosity of pharmaceutical tablets, are important material characteristics that can be assessed from solid density measurements. Two Anton Paar instruments – the Autotap and Ultrapyc 5000 – provide tapped density and skeletal density results, respectively. These extremely accurate volume measurements are required for the pharmaceutical industry and can be correlated to flow and porosity.

For both powder flow information and tablet porosity, measurement of skeletal density using gas pycnometry enables you to assess these important pharmaceutical properties.

1. Introduction

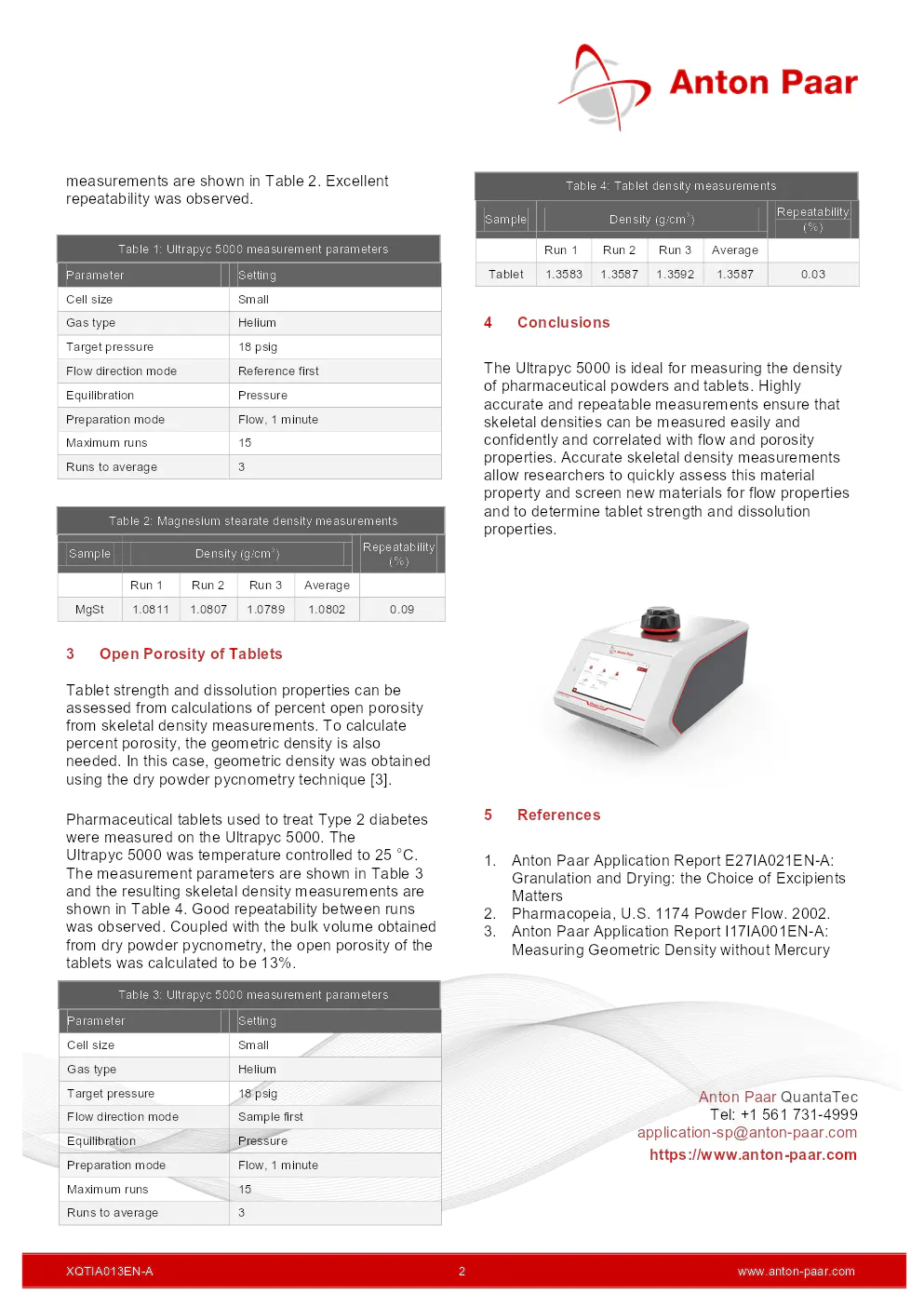

Solid density is an important property of pharmaceutical compounds from powder (drug or excipient) to tablet. Bulk and tapped density are related to flow properties of powder. Geometric and skeletal densities enable the calculation of open porosity of tablets, and skeletal density is related to the crystallinity, polymorphology, and purity of pharmaceutical compounds. The flowability of a powder, in particular of an additive or excipient, is important to determine how that additive will affect the granulation or tableting process. In addition, this characteristic helps to predict the uniformity and dissolution of the final product. For example, good flowability ensures that there is appropriate, uniform filling of capsules such that consistent weight and dosage is achieved.

2. Powder Flow Properties

Magnesium stearate is often used as a lubricant in the manufacture of pharmaceutical tablets, capsules, and powders. However, it can also affect the flowability of the mixed pharmaceutical powder. It is important to understand its solid density properties such as tapped and skeletal density. Tapped density is used to describe flowability through the Hausner ratio (HR) and Compressibility Index (CI).

- Tapped density of a commercially available magnesium stearate was measured using the Autotap and following USP, Method I. An HR of 1.92 and a CI of 48 were obtained for this sample. These values indicate this particular magnesium stearate falls into the category of “very, very poor flow”.

- The Ultrapyc 5000 was used to measure the skeletal density of the same commercially available magnesium stearate following USP. Deviations from the theoretical density of magnesium stearate (1.026 g/cm3) can indicate different hydrates or impurities are present in the sample. Because magnesium stearate is a fine powder, the PowderProtect mode of the Ultrapyc 5000 was utilized to expand gas from the reference chamber to the sample chamber to prevent elutriation of the powder. Measuring in this mode allows high target pressures to be utilized to obtain the most accurate data possible.

Sample measurement parameters are given in Table 1 and the resulting skeletal density measurements are shown in Table 2. Excellent repeatability was observed.

3. Open Porosity of Tablets

Tablet strength and dissolution properties can be assessed from calculations of percent open porosity from skeletal density measurements. To calculate percent porosity, the geometric density is also needed. In this case, geometric density was obtained using the dry powder pycnometry technique. Pharmaceutical tablets used to treat Type 2 diabetes were measured on the Ultrapyc 5000. The Ultrapyc 5000 was temperature controlled to 25 °C. The measurement parameters are shown in Table 3 and the resulting skeletal density measurements are shown in Table 4. Good repeatability between runs was observed. Coupled with the bulk volume obtained from dry powder pycnometry, the open porosity of the tablets was calculated to be 13%.

4. Conclusions

The Ultrapyc 5000 is ideal for measuring the density of pharmaceutical powders and tablets. Highly accurate and repeatable measurements ensure that skeletal densities can be measured easily and confidently and correlated with flow and porosity properties. Accurate skeletal density measurements allow researchers to quickly assess this material property and screen new materials for flow properties and to determine tablet strength and dissolution properties.

5. References

- Anton Paar Application Report E27IA021EN-A: Granulation and Drying: the Choice of Excipients Matters

- Pharmacopeia, U.S. 1174 Powder Flow. 2002.

- Anton Paar Application Report I17IA001EN-A: Measuring Geometric Density without Mercury