Vendu par :

Type de produit

1 professionnels intéressés

Posez une question sur le produit

Poser une questionAutres produits de MICROMERITICS FRANCE

-

![]()

AccuPyc II 1340 PycnometerAccuPyc II 1340 Pycnometer

MICROMERITICS FRANCE

3 professionnels intéressés1012 consultations récentesRecevoir un devis -

![]()

GeoPyc 1360GeoPyc 1360

MICROMERITICS FRANCE

2 professionnels intéressés596 consultations récentesRecevoir un devis -

![]()

Multivolume Pycnometer 1305Multivolume Pycnometer 1305

MICROMERITICS FRANCE

3 contenus liés2 professionnels intéressés487 consultations récentesRecevoir un devis -

![]()

AutoPore IVAutoPore IV

MICROMERITICS FRANCE

1 professionnels intéressés675 consultations récentesRecevoir un devis -

![]()

SediGraph 5120SediGraph 5120

MICROMERITICS FRANCE

1 professionnels intéressés614 consultations récentesRecevoir un devis -

![]()

Gemini VII 2390 Surface Area AnalyzerGemini VII 2390 Surface Area Analyzer

MICROMERITICS FRANCE

1 professionnels intéressés568 consultations récentesRecevoir un devis

Produits similaires au DYNAMIC VOID VOLUME ANALYZER 4000

-

![]()

DMA 35Densimètre portable

ANTON PAAR

2 contenus liés24 professionnels intéressés1735 consultations récentesRecevoir un devis -

![]()

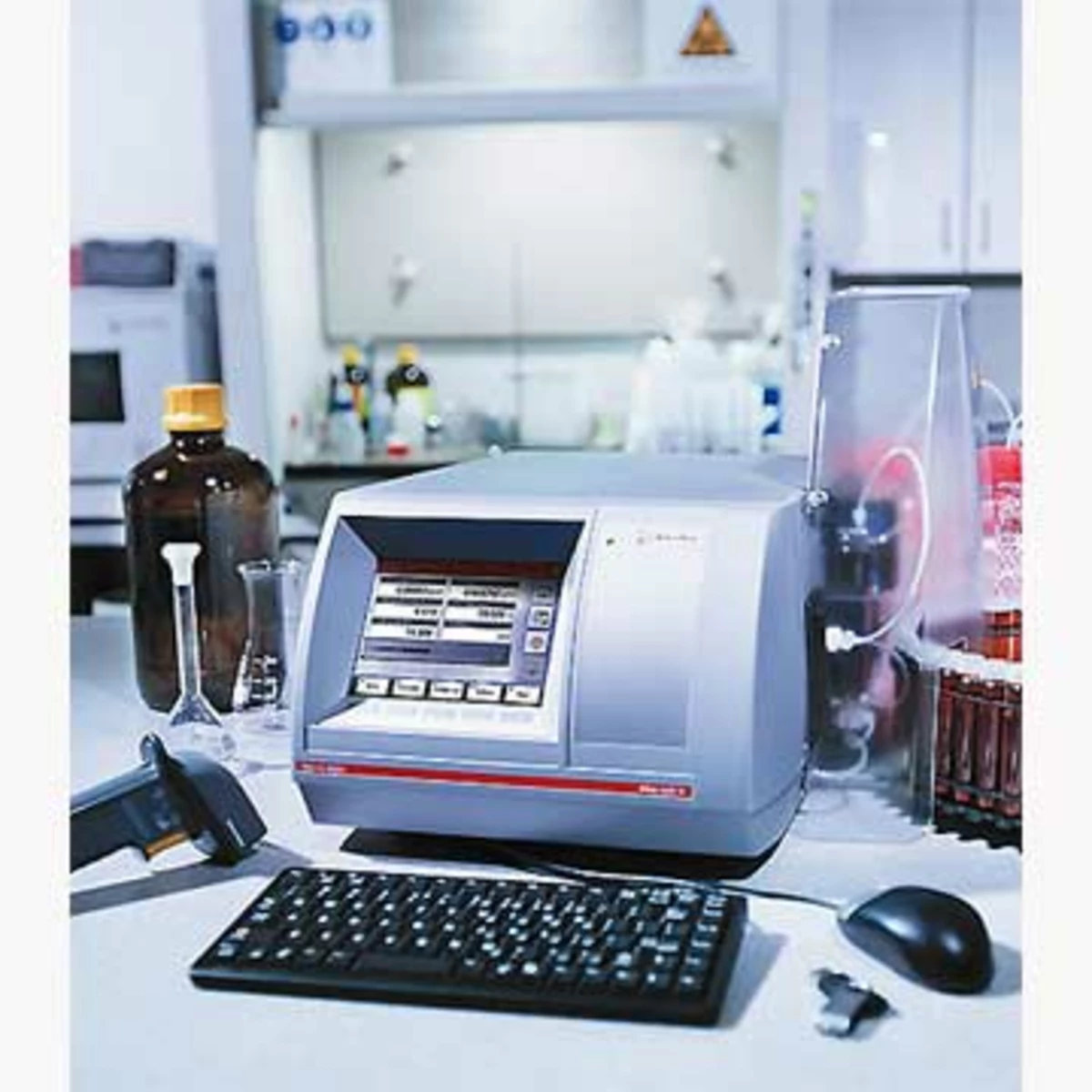

DMA 4101 / 4501 / 5001Densimètres de paillasse

ANTON PAAR

19 professionnels intéressés1233 consultations récentesRecevoir un devis -

![]()

Densimètre portable DMA 35

ANTON PAAR

2 contenus liés17 professionnels intéressés1249 consultations récentesRecevoir un devis -

![]()

DMA 35 BasicDensimètre portable

ANTON PAAR

15 professionnels intéressés1119 consultations récentesRecevoir un devis -

![]()

DSA 5000 MAppareil de mesure de la masse volumique

ANTON PAAR

12 professionnels intéressés753 consultations récentesRecevoir un devis -

![]()

DMADensimètre numérique compact

ANTON PAAR

8 professionnels intéressés963 consultations récentesRecevoir un devis -

![]()

Densimètre DMA 500

ANTON PAAR

4 professionnels intéressés1134 consultations récentesRecevoir un devis -

![]()

Densimètre DMA Génération M

ANTON PAAR

4 professionnels intéressés772 consultations récentesRecevoir un devis -

![]()

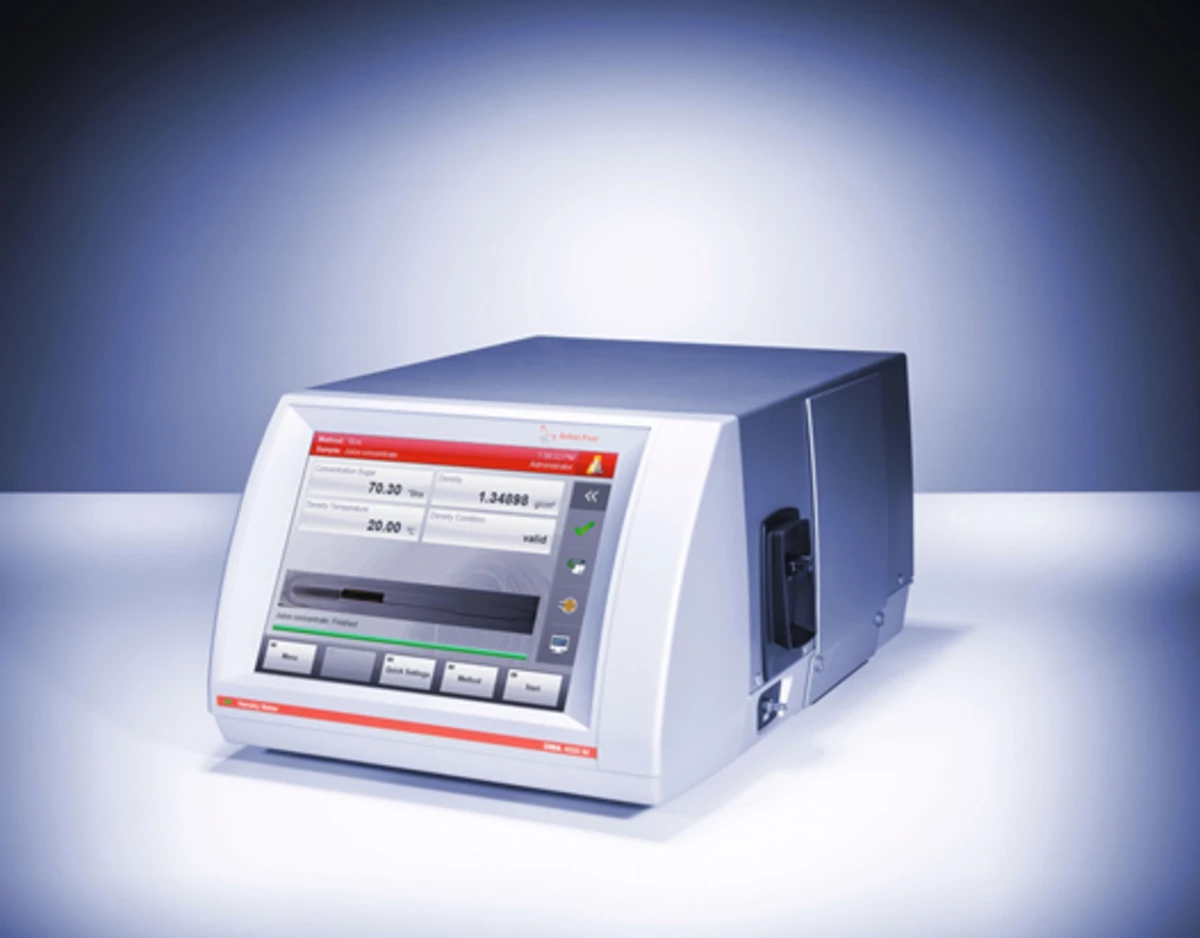

DMA 4200 MDensimètre

ANTON PAAR

2 professionnels intéressés585 consultations récentesRecevoir un devis -

![]()

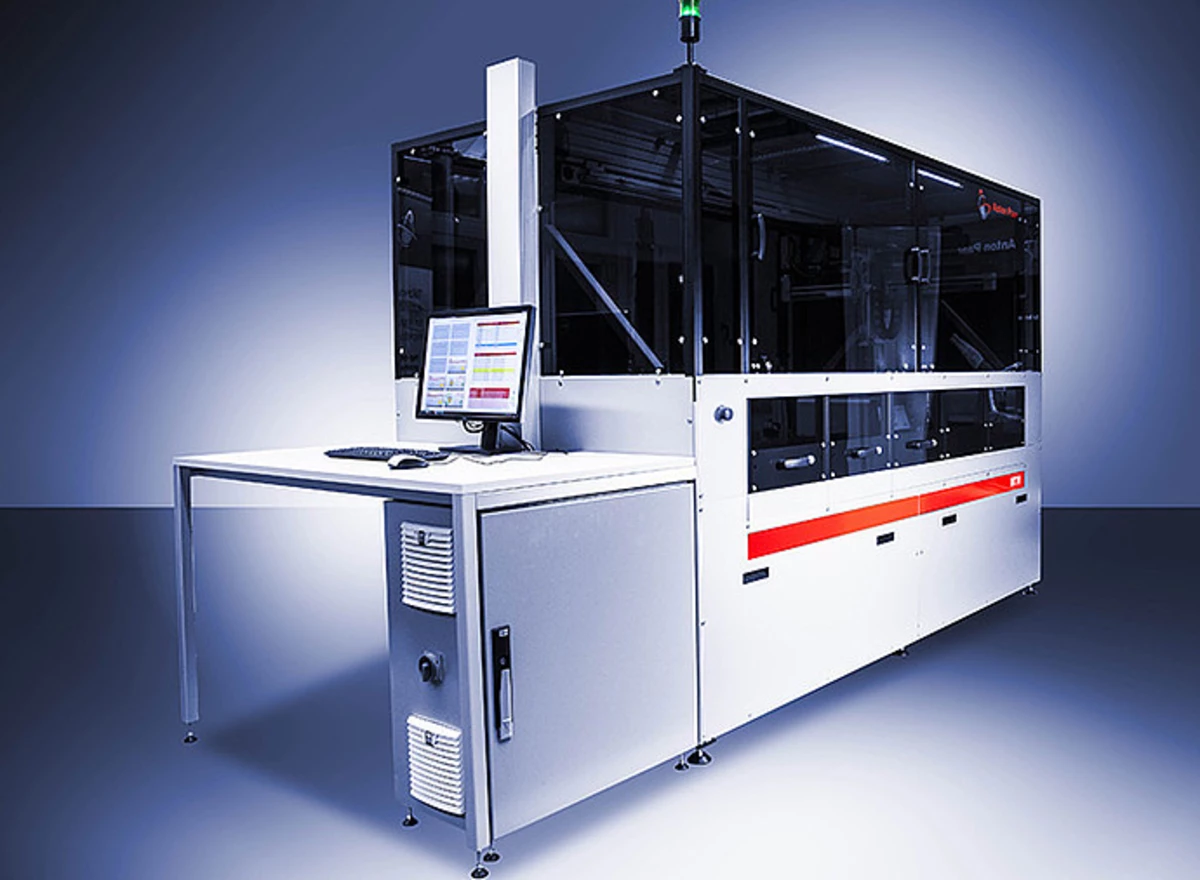

HTX Solution d'automatisation de laboratoire entièrement personnalisable

ANTON PAAR

2 professionnels intéressés417 consultations récentesRecevoir un devis -

![]()

DietQC MESystème d'analyse de boissons diététiques

ANTON PAAR

2 professionnels intéressés410 consultations récentesRecevoir un devis -

![]()

DMA 4500 MDensimètre

ANTON PAAR

7 contenus liés1 professionnels intéressés1592 consultations récentesRecevoir un devis