brochure sur l'analyse de la bière par anton paar

présentation des solutions d'analyse de bière d'Anton Paar

Contenu du document

Solutions pour votre excellente bière

Analyse de laboratoire pour votre excellente bière

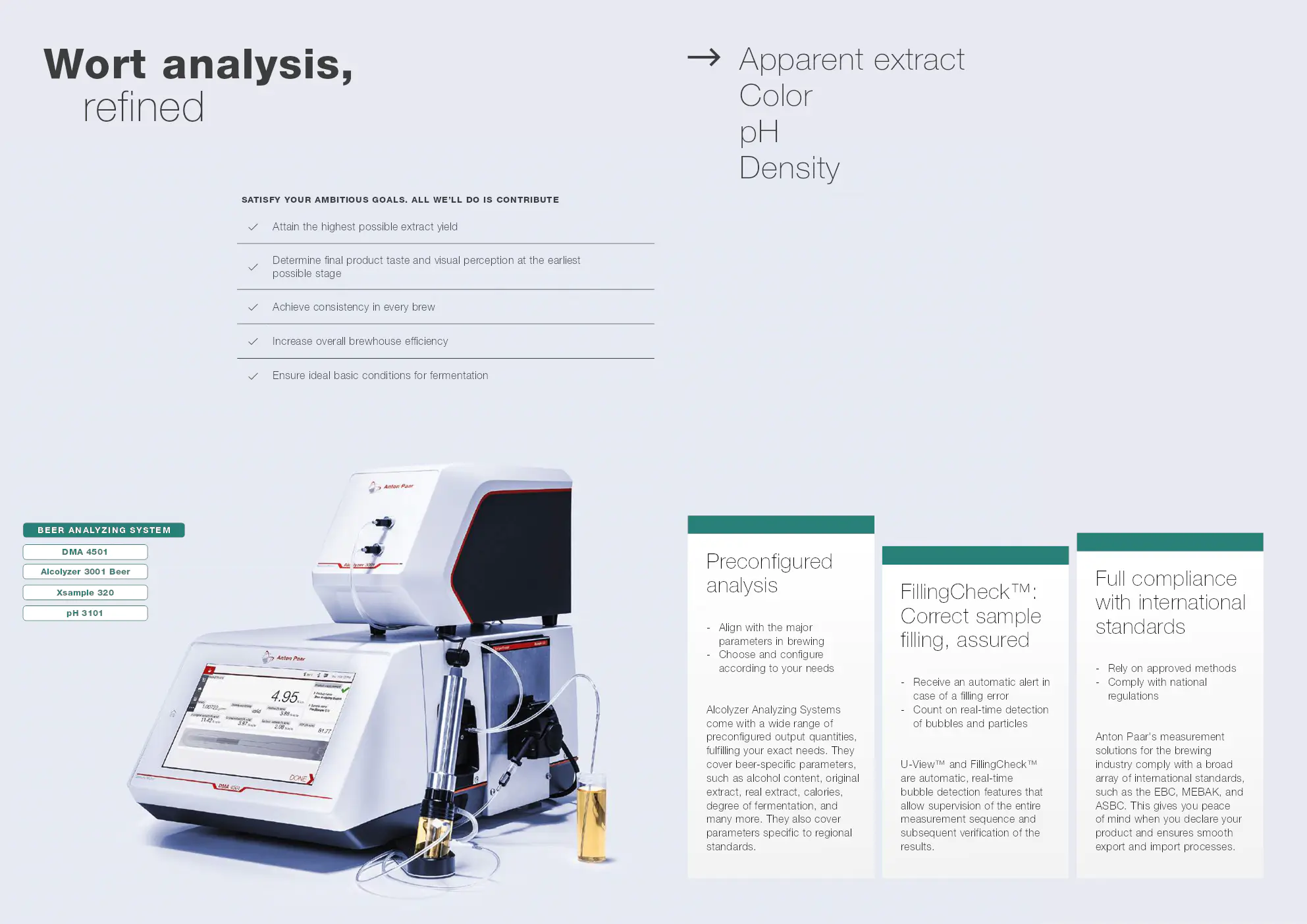

Anton Paar est fier d'avoir passé des décennies à peaufiner des solutions d'analyse de bière pour chaque étape de votre processus de production. Elles sont intelligentes, intuitives et automatiques. Testées par le temps, elles sont un avant-goût de l'avenir. Laissez-nous vous aider à produire une excellente bière.

- Respectez les normes de qualité les plus élevées avec jusqu'à six paramètres, 9x plus rapide que les systèmes conventionnels.

- Couvrez toutes les tâches d'analyse de la manière la plus efficace possible, du moût au produit fini, avec un seul système de laboratoire.

- Maximisez et optimisez la capacité de production grâce à une calibration automatisée et un nettoyage minimal, économisant ainsi deux heures par jour.

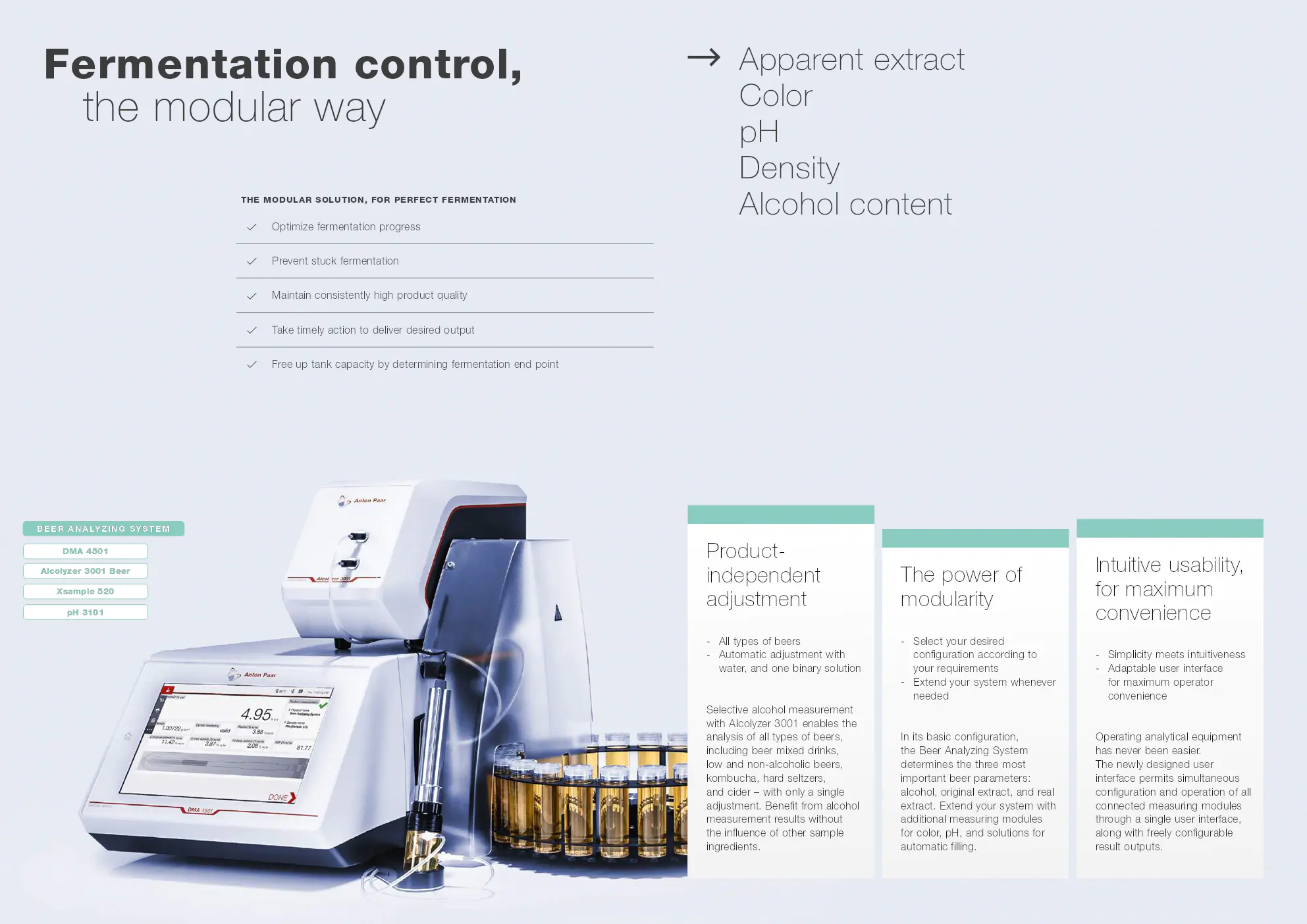

Contrôle de la fermentation

- Réduisez les temps de fermentation au minimum et assurez une qualité de produit supérieure.

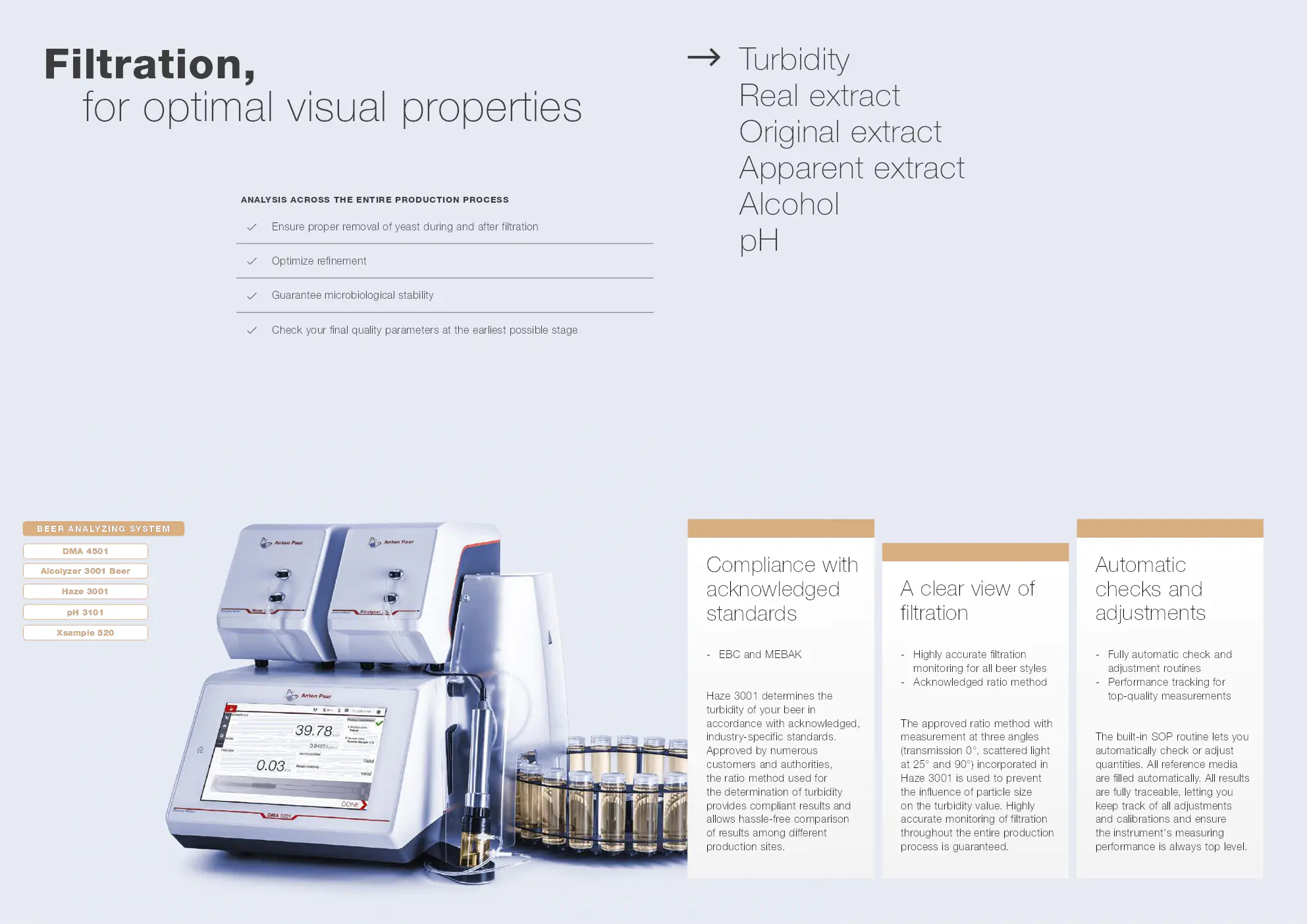

Filtration

- Optimisez et sécurisez votre processus de filtration.

Stockage

- Effectuez une dernière vérification pour une finition parfaite.

Conditionnement

- Mesurez vos paramètres de qualité finaux sans besoin de préparation d'échantillon et garantissez les spécifications de votre produit.

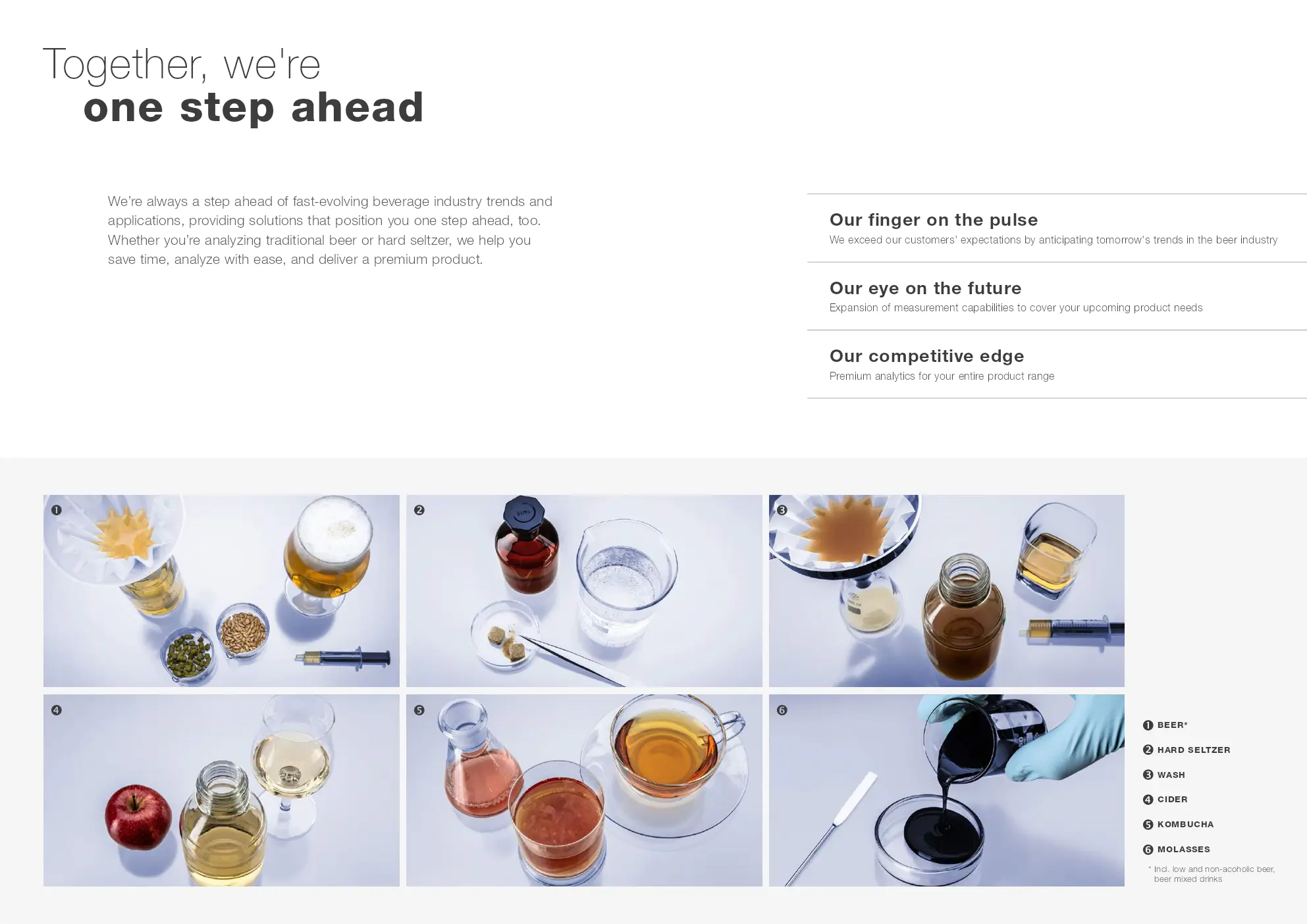

Ensemble, nous sommes un pas en avant

Nous sommes toujours un pas en avant des tendances et applications de l'industrie des boissons en constante évolution, fournissant des solutions qui vous placent également un pas en avant. Que vous analysiez de la bière traditionnelle ou du hard seltzer, nous vous aidons à gagner du temps, analyser facilement, et offrir un produit premium.

Nous dépassons les attentes de nos clients en anticipant les tendances de demain dans l'industrie de la bière.

Expansion des capacités de mesure pour couvrir vos besoins en produits à venir.

Analytique premium pour votre gamme de produits entière.

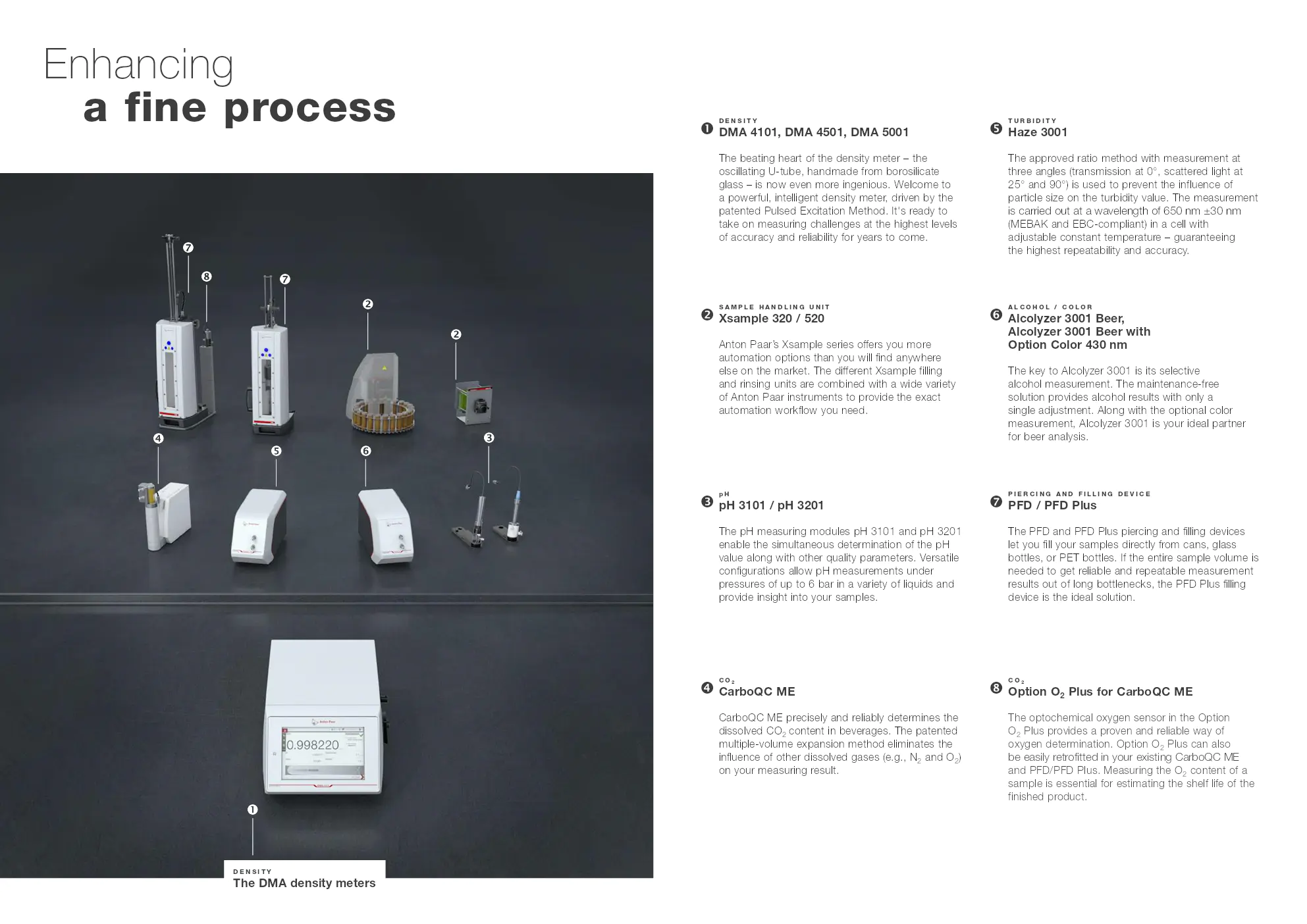

Système d'analyse de bière

- DMA 4501 : Analyse le moût raffiné et la fermentation de manière modulaire.

- Alcolyzer 3001 Beer : Pour la mesure sélective de l'alcool et de la couleur.

- Xsample 520 : Gestion automatisée des échantillons.

- pH 3101 : Mesure simultanée du pH avec d'autres paramètres de qualité.

- Haze 3001 : Détermine la turbidité conformément aux standards industriels reconnus.

Stockage et mise en bouteille

- Alcolyzer Beer M : Détermination sélective de l'alcool et mesure de couleur avec contrôle précis de la température.

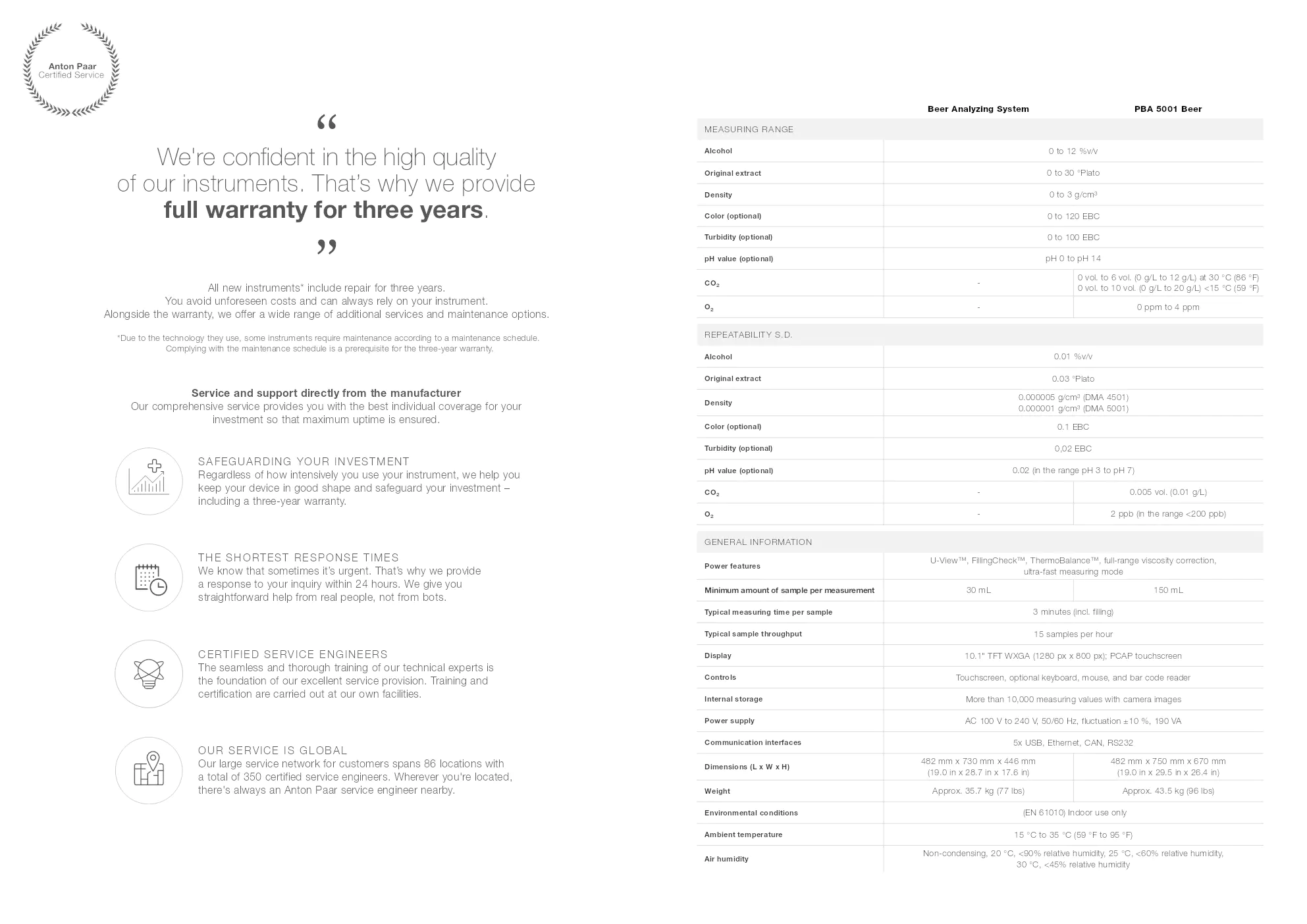

- PBA 5001 Beer : Analyse routine rapide et fiable, sans préparation d'échantillon.

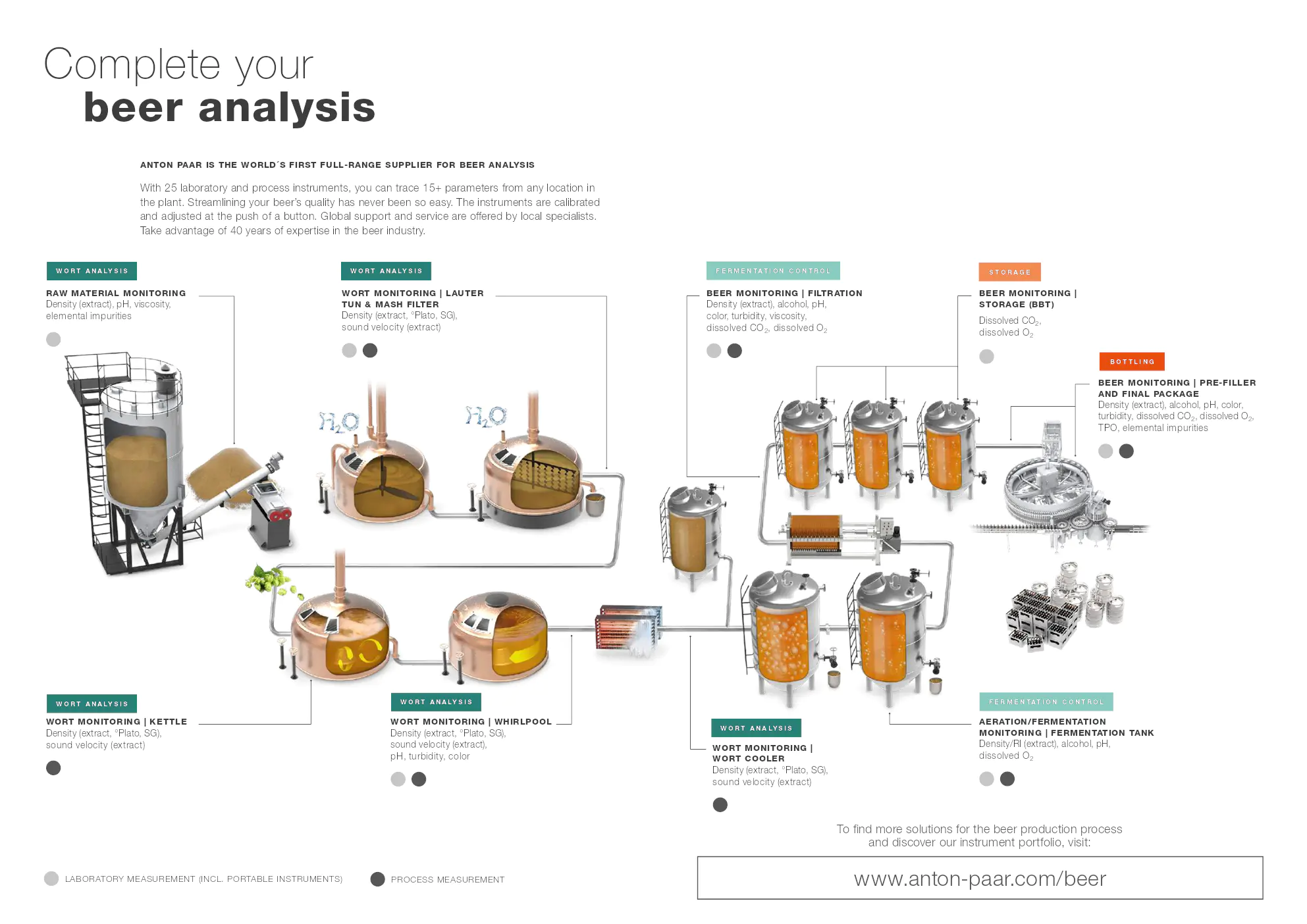

Compléter votre analyse de bière

Anton Paar est le premier fournisseur de solutions complètes pour l'analyse de la bière, avec 25 instruments de laboratoire et de processus, vous pouvez tracer plus de 15 paramètres de n'importe quel endroit dans l'usine. Améliorer la qualité de votre bière n'a jamais été aussi facile. Les instruments sont calibrés et ajustés d'une simple pression sur un bouton. Le support et le service mondiaux sont offerts par des spécialistes locaux. Profitez de 40 ans d'expertise dans l'industrie de la bière.